Why is temperature control important to the cannabis industry?

When it comes to extraction, the name of the game is purity.

For the ultimate in cannabis product, short-path distillation is what the extraction industry turns to for the best possible results.

Distillation, chromatography, and re-distilling the product for purification can remove a lot of inactive compounds that serve no therapeutic purpose.

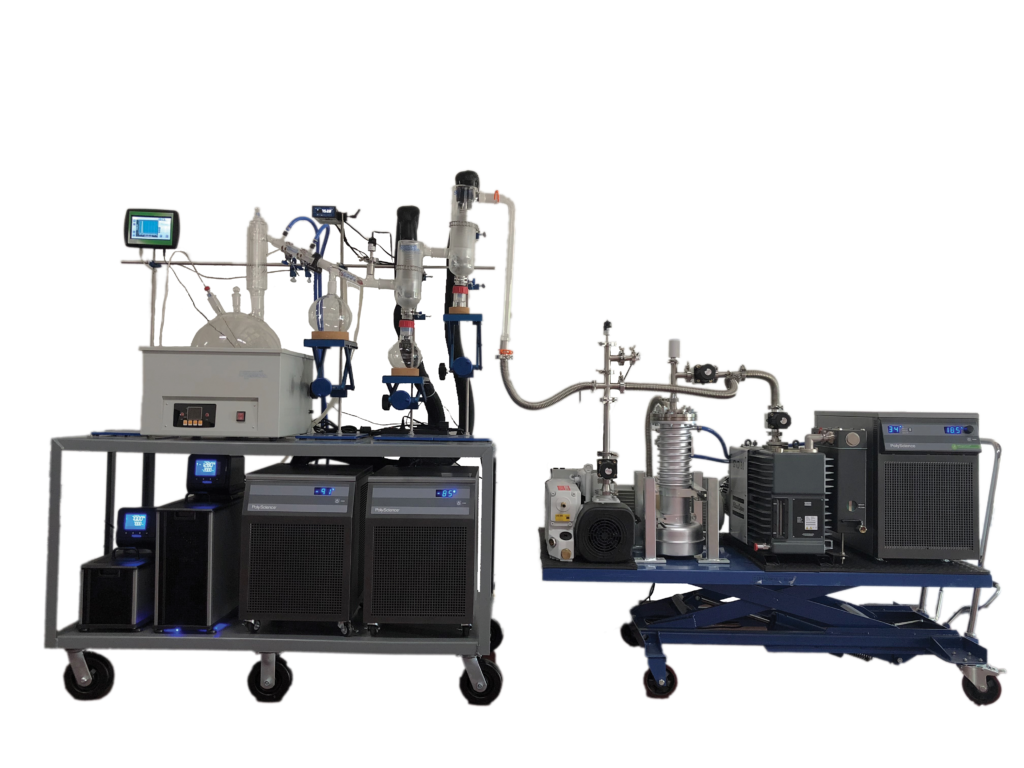

It takes sophisticated, highly-calibrated components to allow companies to reach the level of purity that short-path distillation can obtain.

While there are many factors that go into creating quality product in the cannabis industry, temperature control is one that is at the top of the list.

At PolyScience, we have been working in temperature control for 60 years and if you have a few hours, we are happy to tell you all about it.

Instead, we reached out to President of Summit Industries Elliot Kremerman to discuss the need for quality temperature control in the cannabis distillation process.

Kremerman and the team from Summit are the industry leaders that others turn to for advice when it comes to short path distillation.

He shares how Polyscience equipment works in tandem with his processes.

Safety First.

You can’t have a great product if you aren’t safe.

How does proper temperature control and safety come into play?

As Kremerman explains, there are those who don’t take the proper measures when it comes to temperature control, but it’s a recipe for disaster and low-quality product.

“People are actually out there using ‘stills,’ like the moonshiners used to use. The still model of distillation can result in a low-quality product as well as a dangerous work environment. Open boiling can lead to flammable and explosive chemicals in the air, which can lead to explosions. The proper tools and temperature control can keep your lab safe and functioning effectively,” he noted.

Quality goes way beyond the plant. Why is temperature control important to quality?

There are many variables that go into producing a quality product, Kremerman says being able to control as many of those variables as you can is the difference between success

and failure.

Kremerman recalls: “A couple years ago, manufacturers were not aware how clean you can make a product. In the process of distillation and even in chromatography and redistilling the product for purification, we can remove a lot of the inactive compounds that serve no therapeutic purpose.

“When you’re consuming dirty cannabis, there are parts of it that are therapeutic and then there are parts that are dissolved — like fats, waxes, proteins, or even bad flavor. You can remove the dissolved parts and create a flavorless product that’s very high in purity and actually clean and safe to consume.”

Summit didn’t get here alone.

It takes sophisticated, highly-calibrated components to allow them to reach the level of purity that they are obtaining.

This is where the highly-specialized team of temperature control experts at Polyscience comes in.

What happens to the quality if temperature control isn’t precise?

Precision is vital in every step of distillation.

Kremerman explains: “You have a lot of heat and you have a lot of cooling, if those parameters are off you can be selecting different molecules or you could be having clogs in the system or you can be damaging your pumps.

“People often complain about a darkness in extracts, or a foul odor or taste. This can all be due to degradation.

Oxidation can cause product to go from a lighter yellow to a darker yellow. You’re just distilling in a glass or stainless-steel apparatus with extracts that are hydrocarbon.”

He continued, “Once you’re getting to distillate and to oils that have been further purified, winterized, evaporated, and distilled, you should be getting a nice color because you’re eliminating a lot of the fats and lipids.

If you’re vaporizing or frosting the extract in order to decarboxylate and consume it, you’re consuming a carcinogen. Fats and lipids turn into something that’s bad for your lungs.

“None of the equipment we manufacture would be able to operate at precision performance and exact temperature control without PolyScience chillers.”

What about cheaper options for equipment, does it matter?

Kremerman offers this explanation as to why quality is their primary concern:

“A lot of our customers like PolyScience chillers because they’ll install them and they’ll run nonstop every day, versus a chiller imported from Germany or China, where if a part fails you almost always have to wait for someone to come and repair it or deliver a part from overseas.”

He continued: “The quality is really important to our customers because they know that if they purchase a product, they’re paying a premium for an American-made product.

But, that quality will ensure that their machines will run every single day.”

Why don’t you manufacture your own chillers?

The Summit team are experts because they aren’t trying to overextend themselves.

Kremerman shared his philosophy:

“I focus on what I do best and rely on the experts to help make me and my company put out the best possible product.

There are companies that make their own chillers out there or private label very unreliable products from China.

“They may be more affordable, but as we have been talking about, they can be dangerous, won’t hold constant temperature, and are poorly made.

PolyScience has been in business for 60 years, they are made in America, and when we do need help we call their office in Chicago and get an expert on the line.”

Kremerman concluded: “When it comes to precise and reliable equipment, PolyScience is a leader in quality, which is key because precision is what counts the most.”

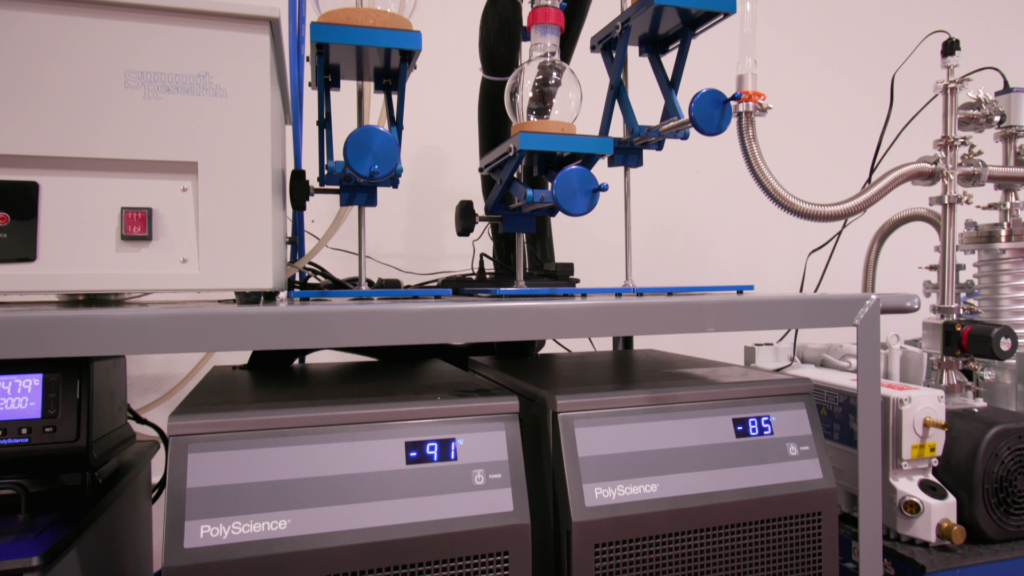

Summit uses PolyScience chillers in their distillation process.

Kremerman touts them as “the heaviest-duty chillers you can get.”

He proudly claims customers can use PolyScience chillers for years before having to recharge and if there is a (rarely heard of) issue, PolyScience takes care of it the same day.

If you are interested in how PolyScience or Summit Industries can help you, please visit www.polyscience.com or www.summit-research.tech.

This post is sponsored. All images courtesy of PolyScience.