Sponsored Content

In the rising tide of the cannabis industry, the forces behind the pre-roll sector are driving a huge portion of that rising tide.

Pre-roll sales in the recreational US cannabis markets saw 59% year over year growth with total sales increasing from $704M in 2019 to $1.12B in 2020. This growth in pre-roll sales outpaced the total market, which grew by 54.2% over the same time.

Pre-roll market share within the cannabis industry has also been steadily increasing over the last two years, rising from 9.8% of total cannabis sales in 2019, to 10.1% in 2020, and is currently sitting at 10.7% for 2021 YTD with a lot of runway to go.

Harrison Bard, head of business development at Custom Cones USA, said every pre-roll brand he encountered has experienced some type of learning curve when they entered the pre-roll industry.

“You need to do your research to understand how to do it right or you likely won’t be successful,” Bard said.

As entrepreneurs flock to the pre-roll industry, Bard said it is crucial to understand the end-to-end pre-roll production process as well as the equipment needed to deliver a high-quality result.

“For many cannabis business owners, this is their first start-up, or they’ve been successful in a completely different industry.” Bard said, “Business owners need to be open minded that what worked for them at their last company may not work with this new business.”

As with all things, Bard said it is best to start at the beginning: the cannabis.

Firstly, brands need to understand where their cannabis supply is coming from. If a company is vertically integrated, then they are growing their own and will be able to tightly control the various inputs and outputs. Those sourcing bulk flower in the open wholesale market would want to establish a solid, wholesale connections to get their flower at consistent quality and prices.

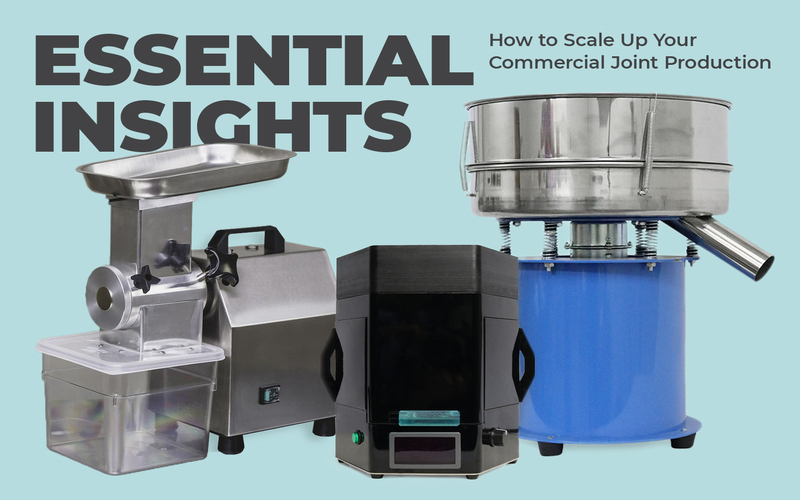

Step 1: Grinding

Cheese graters, blenders, coffee grinders. You name it—people have tried to grind weed with it.

It’s normally done with your hands, so how much more to it can there be at scale? Turns out quite a bit.

Grinding is a process that takes time and precision, but it is often not given the respect it deserves in the pre-roll production process.

“People are still using coffee grinders and blenders that shred the cannabis into a dusty powder, leading to a harsh, uneven smoke,” Bard said.

Turns out, there is a way to do it right.

Once you have your product, Bard recommends the Industrial Cannabis Grinder, which uses a low-RPM, high-torque system that essentially pushes the cannabis through variable mesh screens, which come in three different sizes. These mesh screens allow you to carefully control the particle size, which will effect how your pre-rolls burn and taste.

The industrial cannabis grinder also creates far less heat with it’s low RPM, high torque motor, compared to blenders that use a low torque, high RPM motor. These differences lead to a more even and consistent grind to help deliver an even burn and smooth draw.

So much for the cheese grater.

Another great option, Bard said is the Shred Sifter. This is the same model carried by Futurola, but cheaper. He said this shedder works so effectively that if left on for a couple seconds too long, it can grind your cannabis into powder.

“It works well, but it is not as precise or easy to operate as the industrial cannabis grinder,” Bard said. “We’ve had owners tell us they are the only one that can be trusted to run the shredder, otherwise employees will leave the flower in there too long and turn it to dust – that’s not scalable!”

Step 2: Sifting

When it comes to sifting, Bard said there are two camps: those who don’t sift and those who sift inefficiently.

Many new pre-roll businesses make the crucial mistake of not sifting at all before filling their cones.

“Even the best grinder is going to let through some stems from the inner buds,” Bard said. “The sifting process removes all that and fluffs the cannabis to the perfect consistency for packing.”

Even worse, Bard said are those who are using homemade window-screen sifters over 5-gallon buckets or plastic tubs.

“Can you imagine spending hours trying to rub your grind through a window screen?” Bard asked. “There is a better, automated solution out there.”

Bard said he recommends the Quick Sift – Commercial Sifter to prime the primo for packing. The sifter, which can be used with different mesh screen sizes, shakes the cannabis vigorously so only the ground cannabis particles get through.

“The more accurately you grind and sift your flower, the more accurate your pre-rolls will weigh,” Bard said. “If your flower is sifted, you will pour a more even particle distribution into your cone filling machine – if the particle distribution is even, your pre-rolls will be more even to each other.”

Step 3: Filling

Now, it’s time to get to the Big Dance. You have your bulk pre-roll cones and your finely sifted cannabis. It’s time to bring them together in holy matrimony.

Now, chances are you might be using a Buddy Box, Bump Box, or something other kind of inefficient, laborious nightmare that you are passing onto your production staff.

The main issue with these machines is that they are extremely manual and inconsistent.

For this operation, Bard said the key is vibration. There are several machines on the market to vibrate the weed down into the cones, but he personally recommends the King Kone.

The King Kone, Bard said, is the most flexible and consistent cone-filling machines on the market. Flexible, because it can fill most common cone sizes right out of the box (84mm, 98mm, 109mm) and consistent because it reliable fills all the cones each time with its motor driven vibration.

“We always get rave reviews on the King Kone,” Bard said. “Companies love it and many customers even buy 2 or 3 machines to scale up, instead of buying larger, overpriced machines.”

Another effective, albeit less expensive filling machine, is the Fast Fill 55 and 121. Bard said they are smaller and made of plastic but use the same vibration technique to fill the cones. These are great for companies just starting out.

Now, if you are a large pre-roll company, churning out hundreds of thousands of pre-rolls per month, you can also step up to a fully automated pre-roll machine that does everything for you. You add the cannabis, the cones, and it cranks out perfectly made pre-rolled joints.

For this level of automation, there are a few different options for automated pre-roll machines from Custom Cones USA, which will completely automate your entire pre-roll production process.

“With the new technologies coming out, we are seeing farms who used to have 5-10 knockboxes or King Kone filling machines and 10+ employees switch to fully automated solutions.” Bard said. “Not only are they saving money on labor costs, but the pre-rolls are more consistent and even smoke better.”

Step 4: Packaging

In the pre-roll production process, the job isn’t finished until the joints are packaged and ready for sale.

Regardless of packaging type you select, Bard said it’s important to run your packaging process like an assembly line. To help with this, he suggested Work-In-Progress (WIP) Trays that hold your joints upright while they wait for packaging.

“You can really increase productivity and decrease downtime with these trays, many companies use these to move pre-rolls from the filled phase, to the weight checking phase, and then onto packaging” Bard said.

Bard said that as the cannabis market matures, packaging has become an extremely important step in the process.

Are you selling single joints or a multipack? Are child-resistant closures or tamper-evident seals required in your state? Do you want to use a paper cigarette box for small joints or glass tubes for fat blunts?

“There are a lot of decisions to make regarding how you want to present your pre-rolls to your customers,” Bard said. “That’s why Custom Cones USA works to be a one-stop shop for pre-rolls—to make this process easier and more scalable.”

At the end of the day, the customers that enjoy your product need to know that it came from you. Design branding and logos are crucial for any effective cannabis package.

To create and maintain brand loyalty, Custom Cones USA has a custom design studio that can help cannabis brands design their package experience. If you have that covered already, there are labeling, overwrapping, and shrink sleeve machines to help you seal the deal.

“The great thing about shrink sleeves,” Bard said, “is they provide branding and a tamper-evident seal, all in one.”

Bard said that just about every company Custom Cones USA has helped launch in the pre-roll industry went through a learning curve when they first got started. The best way to navigate this new territory, Bard said, is to network with other businesses doing the same thing and make connections with service providers who can help you with technical questions.

“Compared to other packaging companies that just try to sell you a little bit of everything, we have a team of dedicated pre-roll experts that have worked with hundreds of brands across the US and Canada ready to help you with any new project, process, or issue you are facing,” Bard said.

Sponsored Content