Treatment Studies of Various Antimicrobial Solutions on Strains of Cannabis Sativa

By Arnold Howard, Ph.D., Christopher Walsh, Caleb Johnson, Justin Sanchez, Carlos Perea, Kathryn Radovan, and Darrin Potter on behalf of Terra Vera Corporation

What are the effects of antimicrobial solutions on cannabis cultivation and production? The cannabis industry is growing at an explosive rate and the regulations governing the cultivation, processing, and distribution are rapidly evolving. They’re also highly fragmented on a state-by-state basis. With increasing competition, cannabis operators are under tremendous market pressures to decrease costs and increase product differentiation even as they face increasing regulatory scrutiny.

One of the key threats to most cultivators are microbial pest pressures from molds, mildews, fungus, bacteria, and other pathogens that can damage crop value or make it noncompliant and unsellable. Consequently, Terra Vera has studied the effects of various antimicrobial solutions generated electrolytically using commonly available salts and amino acids when used on crops at various stages from propagation to post-harvesting.

Data were collected to assess the ability to control common pathogen threats such as powdery mildew (PM) and similar contamination as well as effect on product quality. Observations also include data on overall room cleanliness, efficacy, root propagation times, and operator safety impact. Recent results and statistically analyzed data from relevant R&D efforts will be shared. Finally, worker safety and environmental sustainability impacts of these treatments will be shared.

Introduction and Motivation

It is a daunting task to rid the world of the toxic chemicals that are damaging the environment and contributing to a public health crisis. Simply put, there must be a better way to treat crops, the planet, and our bodies. Countless studies have linked pesticides to cancer, Alzheimer’s disease, ADHD, and birth defects, and they pose serious risks to our nervous and reproductive system functions. They are polluting fresh water sources and creating havoc in biological and wildlife ecosystems.

Terra Vera is investigating a superior alternative that mimics the human body’s natural immune system. Using biomimicry technology, the product of electrolysis of a precursor containing amino acids and salts in an electrolytic cell can simulate nature’s cellular response to stress by creating activated amino acid solutions.

Terra Vera observed that these solutions can efficiently deliver nutrients to roots, stalks, and leaves while creating a difficult environment for pathogens. Because the chemistry can be generated on-site and on demand, it drastically reduces carbon footprint and eliminates the plastic landfill waste associated with traditional chemical delivery. The authors feel this technology can have a significant impact on the world and particularly cannabis (and related crops such as hemp and hops) agriculture. This is especially important for indoor and multi-level tiered growth environments where pathogen pressure can be the heaviest.

In the legal cannabis industry, it is understood from experience that one of the key challenges inhibiting growth was the inability of cultivators to gain efficiencies and economies of scale to both reduce costs and improve production quality in a safe and sustainable manner. Cultivators in this industry face the same basic challenge as growers of other crops, namely the need to protect crops from unwanted pests and pathogens while maintaining safety and compliance. For cannabis growers, the challenges can be even more daunting as they often grow indoors or in greenhouse settings, making crop infestation a major concern.

Technology Approach

A subset of the co-authors were experienced in a unique technology that generates chemical reactions on-site and on demand. The technology was originally developed by the U.S. Department of Defense and Department of Energy for use in water treatment to disinfect for unwanted and potentially harmful pathogens, including viruses and bacteria. Over time, this technology was spun into use in U.S. E.P.A. regulated water treatment facilities as well as a host of commercial applications.

These co-authors developed a major variation of the technology that mimics our immune system. This new chemistry is highly effective against a broad spectrum of pathogens but is safe and will not harm plants, people, or the environment when used properly. When the needs of the cannabis industry to control biological contamination were paired with the new capabilities of the water treatment, the technology was conceived. After the technology was tested on several crops, it became clear that it could both remediate and prevent some of the more common biological pest issues that often damage or destroy crop value. The technology works on cannabis and would potentially work for other agricultural crops such as hops, hemp, strawberries, cabbage, and wine grapes.

Experimental Method and Results

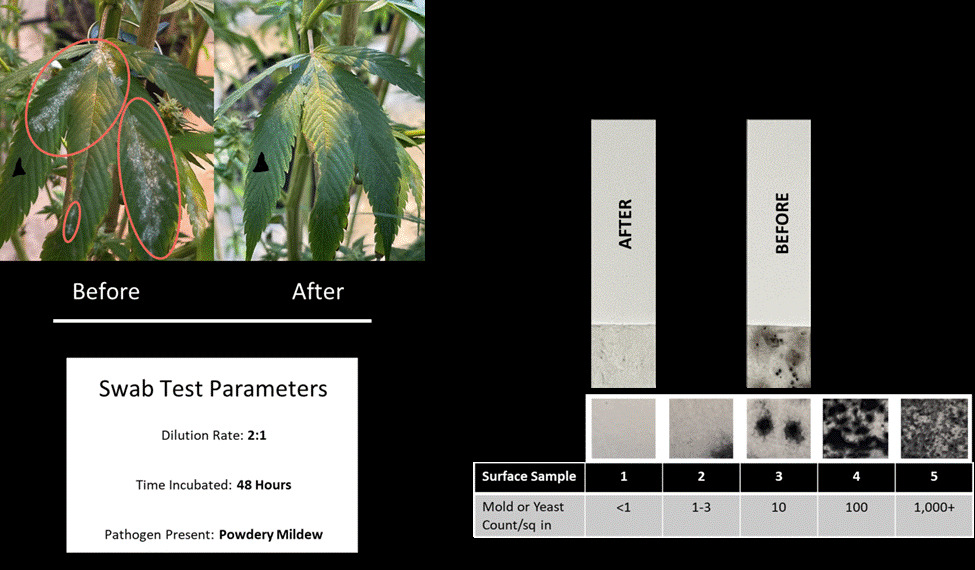

Aqueous solutions of amino acids and salts are activated in an electrolytic cell. As noted above, the electrolytic cell apparatus is described at reference [1]. Various dilutions of these solutions are foliarly fogged or sprayed on a variety of cannabis cultivar plants during growth and post-harvest as well as their grow facilities (see Figure 1) and wiped on work surfaces and plant leaves to demonstrate powdery mildew (PM) remediation (see Figure 2).

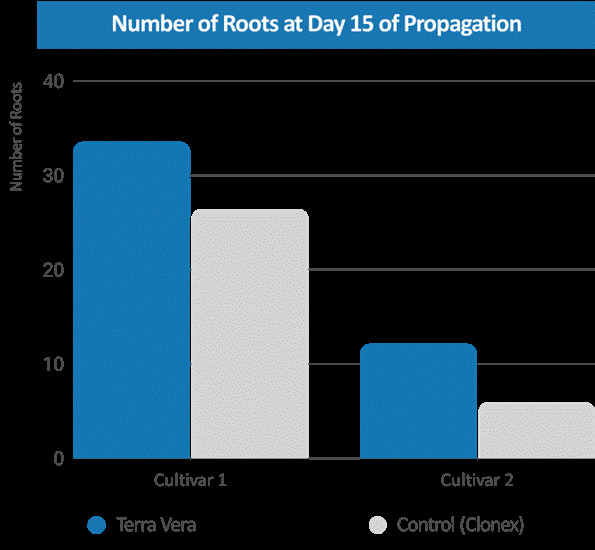

Other dilutions of these solutions are foliarly sprayed on cannabis clone cuttings at several points during cloning and demonstrated faster root production (see Figure 3). Some surfaces of plants were wiped before and after treatment with Sani-Check swabs and incubated in an oven typically for 48 hours at 80 degrees Fahrenheit to promote pathogen growth.

Photos of the Sani-Check swabs (and others of plant leaves) were taken with a standard cell phone. Clones were typically cut from mother plants at a 45-degree angle and propagated in a traditional clone dome on a heat mat set at 75 degrees Fahrenheit.

Clones were foliarly fed with TV solutions at various dilutions or (in the case of Control cuttings with Clonex solution), (see Figure 4 for one clone showing massive root propagation at Day 15 of cloning). Experimental results are provided with description in the corresponding four figures.

Conclusions

Naturally occurring amino acids and salts when electrolyzed treat powdery mildew and molds as demonstrated by plant photos and swab results.

They also serve as a nutrient for accelerated root growth during propagation cloning in a traditional clone dome. Finally, these electrolyzed solutions are safe for workers (with no re-entry interval and minimal PPE required), are safe for the environment, and can be produced sustainably on-site at agricultural farms, eliminating supply chain disruptions.

This article first appeared in Volume 4 Issue 4 of Cannabis & Tech Today. Read the full issue here.

Author

-

Cannabis & Tech Today is the premier publication for inspiring business profiles, exclusive interviews with thought leaders in the field, science innovations, and insights on new legislation and growth in the cannabis market.