As the industry continues to charge forward at a neck-breaking pace and more states and countries implement legal cannabis programs, businesses and regulators are looking beyond the early-stage issues of our industry and are beginning to factor long-term sustainability into their decision-making. Though the product is plant-based and commonly thought of as “green,” producing and distributing billions of dollars worth of cannabis inherently creates significant environmental impact. Governments and businesses are now seeking ways to mitigate that impact by focusing on resource consumption, energy usage, and waste management. This brings into question a key component of many state-operated cannabis programs: one-time use radio frequency identification (RFID) tags composed of plastic.

The damage to the environment caused by plastic waste cannot be overestimated. Several states have banned one-time use plastic bags in grocery stores, some have banned plastic straws, and internationally we have even seen K-Cups being banned. Just this year, researchers from the University of Hawaii determined that certain types of decomposing, un-recycled plastics are actually prolific contributors to greenhouse gases. As the cannabis industry faces increased scrutiny for its environmental impact, there is an opportunity to build an industry that is mindful of its environmental impact on the world. RFID tags have great potential, but deficiencies and lack of usefulness in cannabis settings aside, it would be irresponsible for the industry to continue employing millions of one-time use, non-recyclable plastic tags.

Some Background on RFID Tags

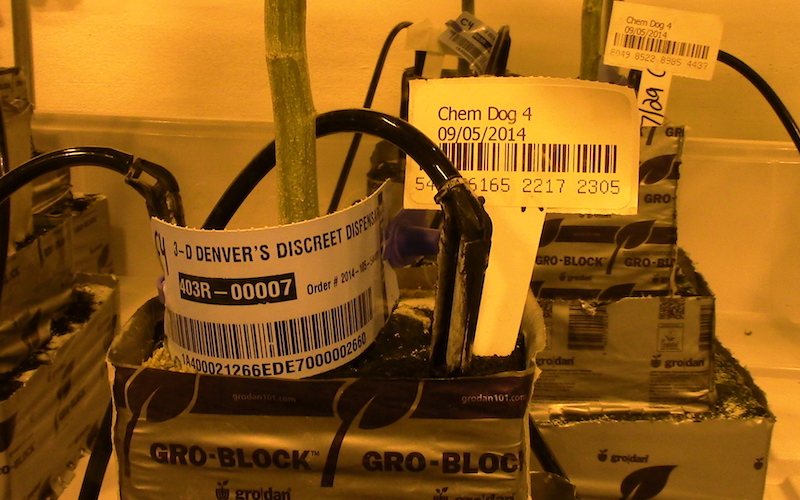

Cannabis regulatory agencies typically use a combination of specialized software and physical tags to track state-authorized product through the entire cannabis life cycle from seed to sale. The goal is to create an audit trail of any given product so that all parties involved in the supply chain operate transparently and are held accountable. Of the 32 states that have medical or adult use industries, roughly a third of them require that the physical tags attached to plants and inventory are RFID tags, while the rest allow for traditional printed barcodes.

What’s the Difference Between RFID and Barcodes?

In terms of data storage capabilities, there is no difference. Tags are just tags and convey no useful information without the software system. The theory is that RFID tags allow for scanning groups of products to move through large numbers more quickly. However, in practice, few cannabis businesses actually use RFID scanning. Scanning groups of RFID tags does not guarantee that you’re scanning every tag in a given group. In most cases, users find that plants and products get missed due to “shadowing,” where one tag blocks the scan from reaching the tag behind it. Additionally, areas of high density metal and water are known to cause interference with RFID scanners, resulting in read issues. That brings into question the overall effectiveness of RFID tags in cultivation environments, where thorough scanning is essential to effective auditing. Barcodes require that you scan each and every plant or product that is part of a given audit, which can be more time-consuming, but better guarantees accuracy.

Sustainability of RFID Tags

The issue of plastic waste and its outsized impact on our environment is one that has been thrust into the spotlight and can no longer be ignored. Considering RFID tags in the cannabis industry are one-time use, composed of non-recyclable materials, it would be irresponsible for leaders to avoid the glaring question, “Is RFID sustainable for the future of the cannabis industry?”

Ultimately, states must determine which tagging methodology is most advantageous for their framework, industry participants, and ultimately, the patients/consumers. Considering cannabis businesses across the country are literally going through millions of RFID tags a month, the elephant in the room is the fact that nobody in the industry is recycling them.

RFID tags are composed of polyethylene terephthalate, or PET. Under the right conditions, this type of plastic is highly efficient and recyclable. However, inside of each RFID tag is a small metal antenna that is responsible for communicating data to a handheld scanner, which by itself is also recyclable. A key component to effective recycling is the requirement of separating recyclable materials, often referred to in the waste management industry as “sorting.” This sorting is done either in the individual recycling bin (think airports and mall cafeterias) or at a facility. In order to recycle an RFID tag, you would have to manually separate the metal antenna, which is embedded within the plastic device. Considering an average grower can use up to 1,000 tags a month (a very conservative number), it would be a painstaking process to manually remove a small metal piece from each and every RFID tag the business uses.

Picking a Path

Cannabis businesses are inherently cost-intensive and the financial obstacles they face are mounting, making it unreasonable to expect an emerging startup business to spend hours on a task that does not result in ROI. Factor in the endless nature of this process and companies are faced with countless hours spent on a task that does not benefit the business directly.

Regardless, the only real potential benefit of RFID is the appearance of being high-tech, but appearances are not worth the high costs of the tags themselves, nor the irreversible damage to the environment to which they will ultimately contribute.