Across the U.S., pre-rolls are rising in sales and popularity among cannabis consumers. The convenience of pre-rolls allows consumers to avoid the work of rolling their own, a preference that ranks high with the market’s target audience.

But as much as pre-rolls are gaining market share, not all things are looking up for this product category. The products themselves are just as quickly gaining a reputation for hit-or-miss quality and a lack of overall consistency.

This poses a problem for industry operators — one that robotics could potentially solve.

The Current State of Pre-Rolls

There’s no question about it: Pre-rolls are gaining traction in sales. Headset, a cannabis analytics company, recently reported that pre-roll sales increased 38.9% from 2020 to 2022.

Another report shows that in California, the number of online carts that only have pre-rolls went from 47% to 53% in just one year.

But that’s not all. Infused pre-rolls are having a moment, too. Coinciding with the trend toward desiring convenience is a heightened demand for potency.

To keep up with the trends, brands are now infusing pre-rolls with cannabis oil or concentrate to boost potency and meet these unique customer needs.

Senior data analysts at Headset called infused pre-rolls the “segment to watch in 2022,” considering the category took over as the second-largest, with sales doubling in both years.

Infusing pre-rolls adds a whole new element for operators to manage in producing a uniform product that delivers a consistent experience for consumers.

Lacking consistency is one of the fastest ways to self-sabotage a brand. To avoid doing so, facilities are increasingly turning to technology to automate, fine-tune, and elevate the way pre-rolls are made.

Implementing Robotics to Improve Quality

The perfect pre-roll is an art form, as simple as it may appear.

The flower has to have just the right consistency and be packed just the right way to deliver the smooth, even burn that consumers crave.

Today, pre-roll manufacturers are finding it incredibly difficult to achieve this type of precision and accuracy.

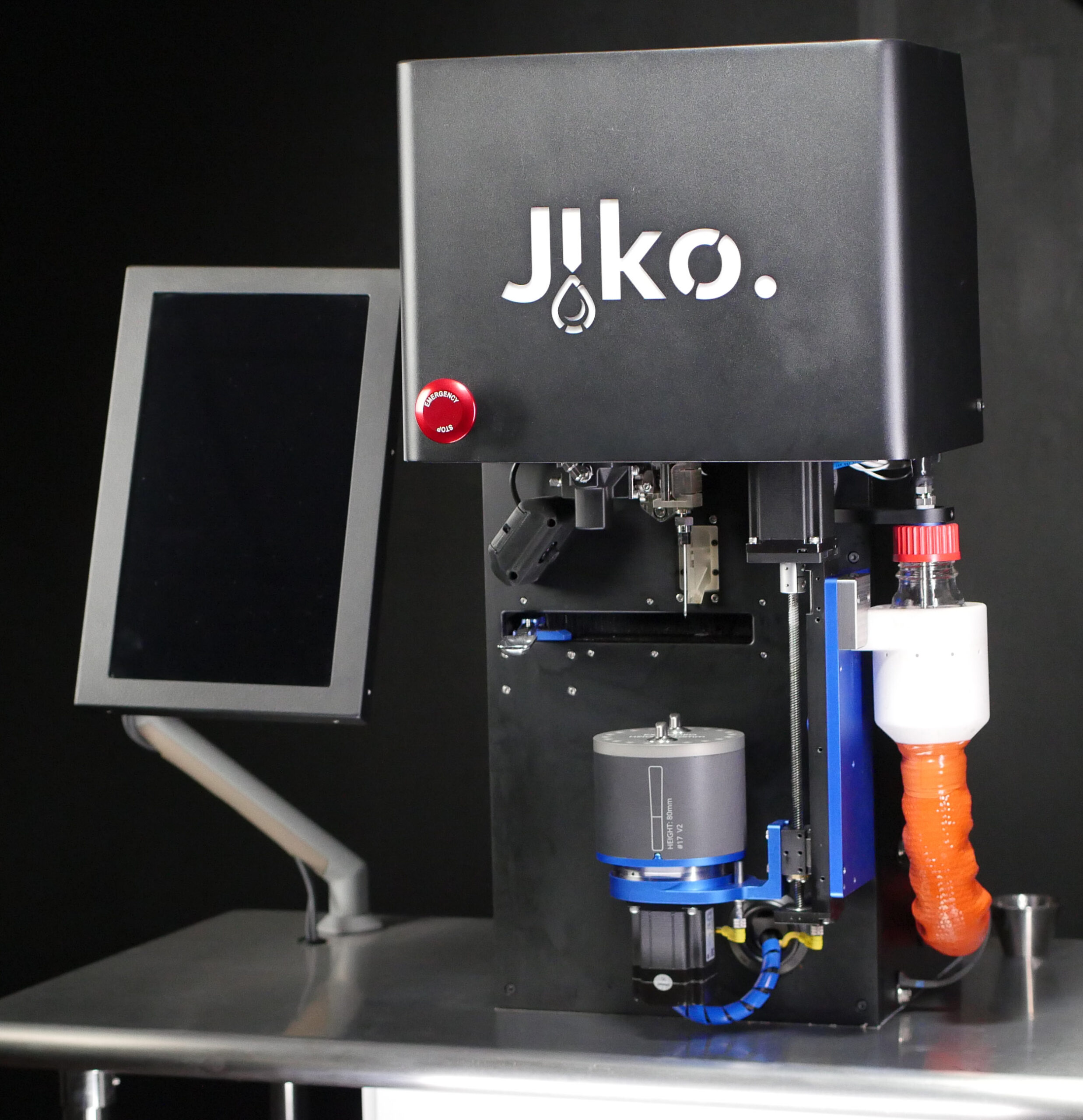

That’s where robotics and automation technology enter the conversation.

With the right equipment, brands can calculate exact ratios and fine-tune mechanisms to produce the perfect pre-roll with every fill.

This not only allows pre-roll manufacturers to automate and scale processes to increase their bottom line, but it improves the end-consumer experience too.

Most operators struggling to make a profit and keep staff might think this type of technology is out of reach. But even though it might take a genius to design and engineer robotics-powered pre-roll infusion technology, it doesn’t take a genius to use the finished product.

It’s not necessary to hire new teams to operate automated systems, which is another benefit of implementing automation technology to improve consistency and quality.

The Future of High-Tech-Powered Pre-Rolls

As the industry evolves, so will product quality and the advanced processes it takes to deliver pre-rolls people can depend upon.

We’ve seen concentrate quality improve over the years, solventless goods take over the game, and now it’s time for pre-rolls to evolve to meet market demand.

So don’t give up on pre-rolls just yet and stay tuned as brands transform from hit-or-miss to tech-powered quality.

This article first appeared in Volume 4 Issue 4 of Cannabis & Tech Today. Read the full issue here.

Author

-

Nohtal Partansky is the Founder and CEO of Sorting Robotics. He is a serial entrepreneur and former NASA-JPL engineer. At NASA-JPL, Nohtal was a cognizant engineer on the MOXIE project; an instrument currently on the surface of Mars producing oxygen from the Martian atmosphere. After leaving NASA-JPL, Nohtal founded Sorting Robotics with his two co-founders, Cassio Dos Santos Jr. and Sean Lawlor. Sorting Robotics builds innovative, AI-driven equipment for cannabis manufacturers and vertically integrated brands.