If you, your parents, your grandparents, and great grandparents all had the same job, would you consider yourself an expert in the field? While that kind of legacy is tough to find in the cannabis space, Fritsch has a century of experience in industrial milling and they’re bringing that expertise to cannabis.

In the Great Lakes State, family-owned businesses are a major part of the economic landscape.

From Detroit’s J.W. Westcott Company (140 years in operation) to Grand Rapids’ Meijer, Inc. (87 years in operation), Michigan is home to many long-lived family businesses.

Melissa Fauth is president and CEO of the U.S. division of Fritsch Milling and Sizing Inc., a 4th-generation family-owned German business specializing in industrial milling and sizing solutions.

While not a Michigan native, Fauth’s expertise is helping cannabis companies nationwide scale their operations.

We spoke with Fauth to learn what makes her company unique and what she’s learned from 100 years of industrial milling and sizing.

Cannabis & Tech Today: What challenges is Fritsch solving for the cannabis space?

Melissa Fauth: Processing operations and laboratories working with cannabis and hemp have lacked access to professional milling instrumentation that was engineered with their unique material in mind.

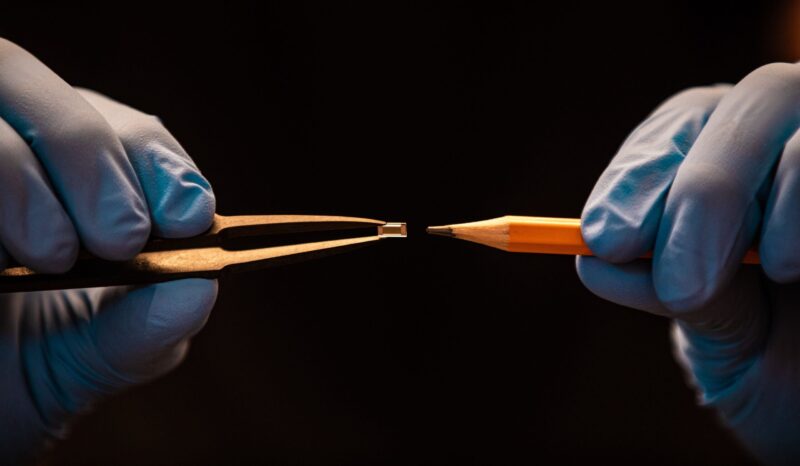

The precision milling systems offered by Fritsch allow clients to prepare their variable starting material with a repeatable outcome, in the most ideal way for their downstream application needs.

The Pulverisette instruments mitigate the occurrence of physical and chemical degradation to maintain the sample integrity and the highest quality yields, for maximized efficiency in production or for analysis.

C&T Today: What makes your solutions unique?

MF: Commitment, experience, and ongoing developmental processes.

Aside from the inherent ROI from material integrity, operational parameter adjustability, controlled and consistent particle size output, temperature mitigation, and ability to follow GLP and GMP principles — the Fritsch Team is unique.

The Pulverisette 19 (P19), for instance, has a long history — decades in fact — of serving food, pharma, and agriculture.

As the emerging cannabis industry blossomed in the Americas, Fritsch business, application, and engineering professionals proactively invested in external collaborations, R&D projects, experienced successes and failures-putting the best suited technology through rigorous trials to engineer a new generation of instruments that were specifically optimized for the attributes of this valuable crop, that is as unique as you and I are.

C&T Today: How is your experience driving innovation within the sector?

MF: Contributions of the past, present and future converge to provide solutions that come from 100 years of technical history, responding to the needs and challenges of today, and striving for continuous improvement as we anticipate the industry goals of tomorrow.

This unique position as a 4th generation family-owned business provides our clients a wealth of experience, from the multitude of industries we serve, for size reduction and particle characterization from agriculture to aerospace.

C&T Today: What does the future hold for Fritsch Milling & Sizing?

MF: Exciting developments are always on the horizon because it is an ongoing process rather than a singular event.

Process automation and production system integration for material handling, monitoring, and conveyance have just launched — offering stock, semi-custom, and fully custom engineering with our partner organization Sample Automation LLC.

Larger volume systems, new construction technologies for surfaces, materials, power, electronics, and temperature control system configurations are primary focus areas.

The opportunities for optimization and development arise from well founded, established, and innovative principles that are quality made in Germany since 1920.