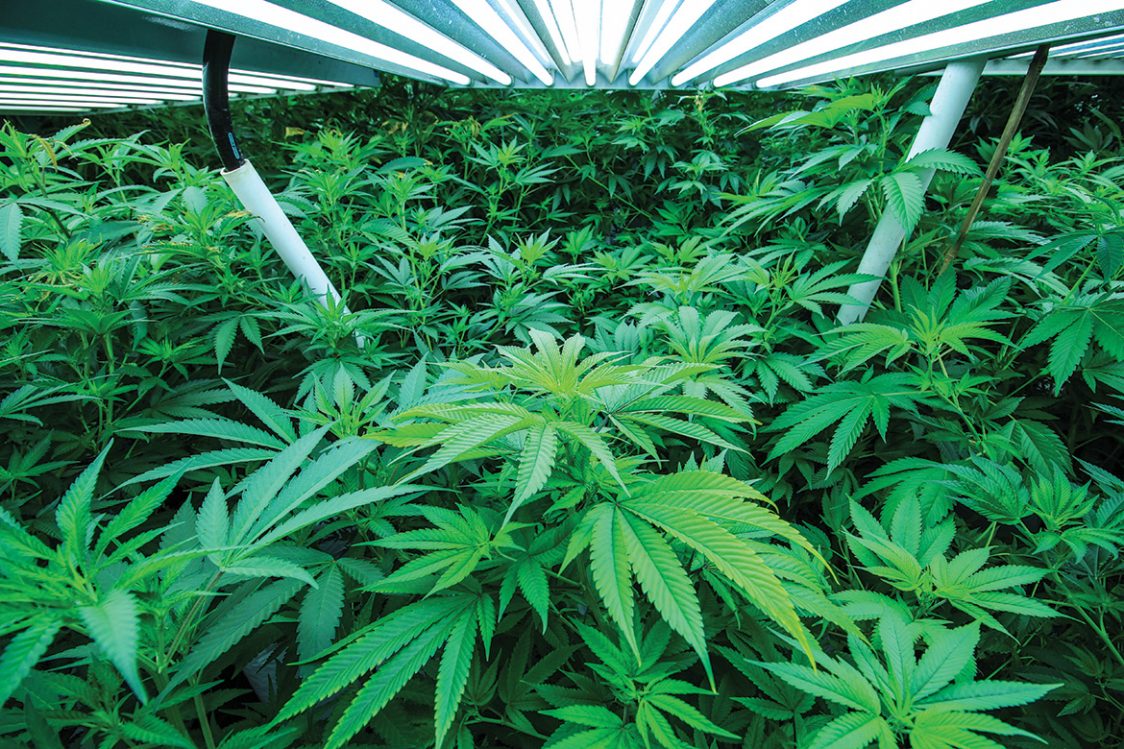

“Growing indoors, you control the entire environment from temperature to humidity to the moistness and temperature of the soils,” Alan Lien, CEO of Solis Tek explains. “With cannabis, you have one single light that can produce an average of one to three pounds a day. The larger the yield and the better the quality, the more money you can get out of it. So, a lot of attention and care goes into how to control the environment around the plant and make the plant as comfortable and as healthy as possible.”

Much of marijuana is grown indoors, in order to maximize environmental control and ultimate yields. But all that “attention and care” that Lien references comes at a cost. As Colorado Harvest Company CEO Tim Cullen explained to Fox News, “We have to recreate the sun in order to get marijuana plants to flower indoors.” This results in the electricity bill for just one of their growhouses reaching $10,000 a month.

In fact, Denver’s Department of Public Health and Environment estimates that the marijuana industry accounted for 3.9 percent of the city’s energy usage in 2016, double the amount used in 2014 when recreational cannabis first started in Colorado. Due to the industry’s youth and stigma, much of the technology used in these grow houses is inefficient or outdated. However, there are those that are attempting to improve energy efficiency in growhouses.

Boulder County, CO, for instance, started the voluntary Marijuana Energy Impact Offset Fund (MEIOF), charging a little over two cents per kilowatt hour for growers. Per their website, the goal is to motivate growers to use more sustainable energy resources:

“Boulder County is requiring commercial marijuana growers to either offset their electricity use with local renewable energy, or pay a 2.16 cent charge per kWh. The fee is being put into the Boulder County Energy Impact Offset Fund. This fund is being used to educate and encourage best marijuana cultivation practices with regards to energy usage as well as to fund other carbon offset projects such as the development of more renewable energy. This program is collecting high-quality energy usage data that will provide researchers the tools they need to develop the most efficient lighting and ventilation systems for this rapidly growing industry.”

There is still much to learn about the cannabis industry and its wider effects on things such as the environment. However, programs like Boulder’s MEIOF help fill the current knowledge gap and motivate industry leaders to critically look at and improve upon their practices.

For the full interview with Alan Lien, check out the summer issue of Cannabis & Tech Today.