Cultivating cannabis can be a challenge. In addition to being a fairly resource-intensive process, the plant itself is quite sensitive to its environment. With operators facing slim margins in many markets, it’s imperative to be as efficient as possible.

Enter AI Grow. A technology company providing automation and data analytics solutions for controlled agriculture, AI Grow was founded with the intention of helping cultivators maximize profitability and performance. Offering custom modular-controlled software for facilities of any size, AI Grow’s one-stop-shop system has the ability to regulate and monitor lights, water, pH levels, nutrients, and environmental conditions with extreme ease.

Founder Chris Ellis has an extensive background in industrial automation, with over two decades spent automating processes in manufacturing, aggregate mining, and other heavily regulated sectors. A number of experiences in cannabis grows led Ellis, a nearly lifelong devotee of the plant, to an “aha” moment nearly ten years ago.

“I kept saying why aren’t we automating this industry? There are so many controllable devices,” said Ellis, who also serves as AI Grow’s president and CEO.

As it turned out, the mainstream firms simply weren’t ready for what the future held. “I pitched the concept to my old bosses, and they laughed at me,” Ellis recalled.

The engineer didn’t give up. He decided to form his own firm called Assured Integration in 2017 along with partners Daryl Denison and Chris Gibbs. It wasn’t until two years later, however, when the trio officially launched AI Grow that Ellis’s cannabis dreams were fully realized.

While searching for the perfect space to develop his automated grow technology, Ellis and his wife, Shelli, came across an apple orchard for sale just a short drive from Minneapolis. They decided to set up a prototype grow room inside one of the barns, with Ellis playing mad scientist at the helm to perfect his processes. The venture paid off, and AI Grow was soon setting its sights on large-scale commercial cultivation facilities throughout the country.

Cutting-Edge Technology Made Simple

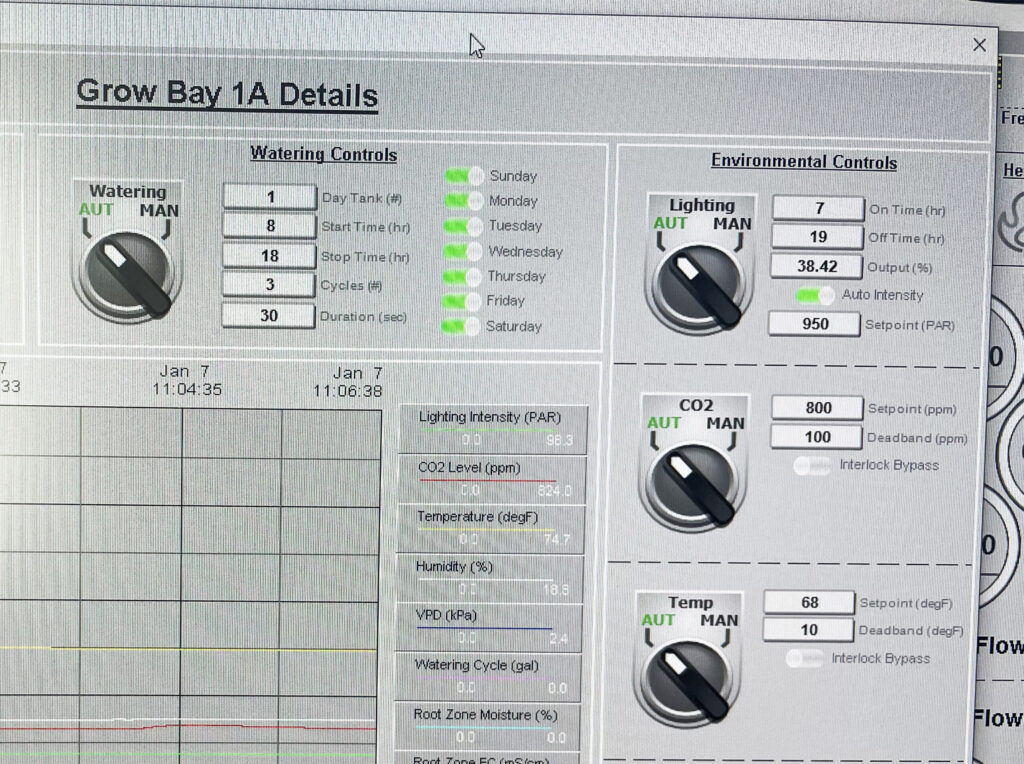

Ellis and the AI Grow team aim to develop and implement systems that are extremely precise and innovative yet so easy to understand that an individual with little to no training could operate them. They do not require the use of proprietary hardware, guaranteeing integration with their software regardless of what type of valve or pump is being deployed. Cultivators can opt to automate certain processes and scale up as they see fit — AI Grow evolves with its customers’ businesses.

A large-scale electrical panel is custom designed by the AI Grow team according to each client’s specific needs. Once manufacturing is completed by a vendor partner, Ellis and his fellow engineers proceed to program and test every touchpoint in the system before it’s delivered. All equipment deployed is best-in-class, industrial-rated to ensure peak performance.

“We prefer to be involved right from the start of a project when the facility is being designed, so we can assist with creating efficiencies within the design that make sense in terms of automation process flow,” explained Daryl Denison, AI Grow’s chief operating officer.

Each control touchpoint on every plant is represented on a flow pattern that is simple to discern. Alerts can be set to notify operators of any issues, both within the facility and via remote access in case of staff shortages or after-hours emergencies. This reduces the risk of catastrophic failures that can put entire crops at risk.

Stored data can be compiled to analyze growth cycles or for compliance purposes. AI Grow uses technology typically only seen in large-scale commercial settings to help set cannabis cultivators up for success.

“We use PLC, short for programmable logic controller. These are the exact same systems that are running your mega manufacturing facilities,” Ellis noted.

Proprietary “Birdhouse” Sensors and Fertigation Systems Round Out AI Grow’s

Full Suite.

Constantly innovating, the team at AI Grow has already developed two standalone product offerings that can integrate with their software with more in the works.

The company’s patent-pending Birdhouse is an aptly-named hanging sensor mechanism that monitors environmental conditions throughout grow facilities. It contains sensors for lights, CO2, temperature, and humidity levels which all feed information into the PLC. The 3-D printed Birdhouses provide additional data touchpoints crucial to ensuring conditions are ideal at all times and are especially useful in dry/cure rooms.

Another AI Grow innovation is their customizable fertigation system which allows cultivators to create their own nutrient blends. Programmable pumps automatically add precise ingredients to water in a solution tank which can then be administered to plants within the larger AI Grow system. Recipes can be stored in a database and used cycle after cycle.

“Instead of buying the cake mix off the shelf, you’re baking your own — it offers total flexibility and cost-savings since you’re using the raw ingredients,” Ellis said.

Sustainability is a Key Driver of AI Grow’s Mission

AI Grow prides itself on helping cultivators be efficient, but the company also strives to make the industry more environmentally friendly while simultaneously reducing bottom lines. Call it automation with a conscience.

“Automation delivers the same amount of resources consistently to the plants, whether it is water, CO2, nutrients, or environmental controls,” noted Denison. “This eliminates the overuse and as an added bonus, the plants will respond very positively to this stability,” Denison noted.

“This precision ties into profitability on both ends, both by reducing the costs that go into production and by maximizing yield to a level that could not be achieved manually.”

As a passionate supporter of the cannabis plant, Ellis genuinely wants to see the industry thrive. And after spending so much time working in other resource-intensive sectors, he is excited to put more time and effort into a more regenerative space. “This is growing — we’re giving back to the planet.”

This article was first published in the spring 2022 issue of Cannabis & Tech Today. Read the full issue here.