In an industry already loaded with up-front capital expenditures, the rising costs of electricity and day-to-day operations, price fluctuations, and seasonal oversupply have left cannabis cultivators across the U.S. contending with tighter market conditions than ever.

Cultivators and their partners need a sure thing, a safe bet that stabilizes costs without sacrificing cultivation goals and product quality.

Cultivators need rebates.

Rebates in Action

Energy rebates are the greatest under-leveraged opportunity for cannabis operations. They have the unique distinction of being the only element of an investment that is always net-positive on the balance sheet.

Rebates and incentives reduce—or sometimes negate entirely—capital investments in LED fixtures, HVACD, other hardware, and can be applied to retrofits as easily as new operations. They incentivize efficiency and sustainability, lowering monthly energy costs. When done well, a rebate program aligns with strategic cultivation goals that translate to a better product, a better facility, and a better bottom line.

There are many reasons why cultivators haven’t tapped into rebates’ full potential. Managing a rebate project can feel intimidating or complex. Many don’t have the experience of working with their utility or don’t understand how much money they’re eligible to recover from a given rebate program.

But the savings are there for the taking. For example, one of our clients in Washington State who wanted to retrofit over 800 light fixtures secured rebates for more than 75% of the project cost.

With the upgrade, that customer will save more than 2 million kWh per year—or 41% of their total energy usage—representing almost 1,000 metric tons of reduced CO2 emissions. Their electricity savings alone covered the remainder of the project cost, allowing them to recover the cash flow dedicated to the project within a year.

Another client in Colorado paid nothing out of pocket for their lighting equipment—we covered the up-front capital investment given the rebate award’s potential. That client has seen energy reductions of 43%, amounting to more than $30,000 saved on their energy bill every year—and 330 fewer metric tons of CO2 emissions.

An Oregon-based grower experienced the same with their dehumidifier installation. With a rebate amount close to $300,000, the operation saves more than half a million kWh and more than $42,000 annually.

The Truth About Cannabis Industry Rebates

The perceived intricacies and nuances of rebate programs—which are almost always unique to the individual utility—lead to misperceptions, not to mention a general feeling among cultivators that rebates can be a crapshoot that isn’t worth the time investment in the end.

That doesn’t have to be the case. With a few tips, cannabis operators can feel confident they’re executing a rebate-eligible project that maximizes savings and efficiency along the way.

- You don’t always need preapproval. This is a common misconception that leaves money on the table. Some utilities award rebates for previously installed equipment, so cultivators should always check to see if their equipment upgrades are eligible.

- Seek an objective, expert opinion that factors in cultivation goals. Equipment providers and the utilities themselves don’t always have all the information required to maximize a rebate’s potential.

- It’s possible to receive a rebate in the amount of 100% of project costs. While any rebate amount is a net positive to the balance sheet, some cultivators can secure rebates that completely cover project costs. Combined with energy efficiency native to the most innovative equipment on the market, undergoing a rebate project and reaping the long-term rewards should be the first priority for cultivators as they design or upgrade their facilities.

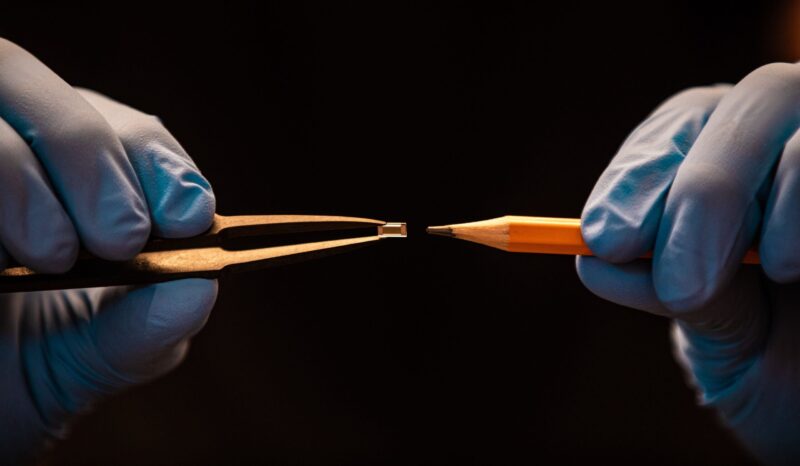

Photo by Alexander Grey on Unsplash