Sweet cherries, crisp apples, and juicy pears aren’t the only agricultural crops sprouting out of Washington. The Evergreen State is also a primary exporter of hops, cannabis, and spearmint. Cannabis contributed $1.85 billion to gross state product in 2020 according to research from Washington State University. Since legalizing adult-use sales in 2012, the sector has seen rapid growth.

Washingtonians spent more on cannabis than alcohol last year, and almost $85 million more than they spent on tobacco products.

The state is also a global hub for information and communication technology. It’s the birthplace of Microsoft, Amazon, Zillow, and Expedia, just to name a few.

Tech goliaths like Facebook, Google, Apple, and Twitter also call Washington home. The state’s Department of Commerce reported their tech sector employment has grown by 34% since 2010.

The technology and cannabis industries are colliding in Washington to produce some incredible innovations. From cutting-edge engineering to automated IT management, it’s a region brimming with ideas and opportunity.

In this Tech Zone, Cannabis & Tech Today takes a look at the West Coast cannabis hub to find the tech and people pushing the industry to new heights. If you’re considering relocating, Washington’s low taxes and affordable cost of living might lure you in.

It’s also America’s top exporter of technology products. Whether you’re drawn to

157-miles of Pacific Ocean coastline or you’re looking to fill one of the nearly

19,000 cannabis-related jobs in the region, Washington has something for everyone.

Let’s take a look at the businesses and innovators shaping the state’s cannabis industry.

What You Should Know About Terpenes

Terpene Warehouse’s Cesare Bonventre explains why natural terpenes are always the best option.

Terpenes. It’s a word thrown around the cannabis industry so often, and it’s unlikely many people even know what it means. To learn precisely what terpenes are and why you should care, we spoke to Terpene Warehouse Partner and ICannaGroup Co-Owner Cesare Bonventre. This is especially important in Washington state, where in 2019, the government enacted a temporary ban on non-cannabis terpenes in vaping products. However, there was no evidence at the time that showed that only allowing cannabis-derived terpenes would make vaping products safer.

“The first thing I like to educate people on is that although all of us on the terpene side of the industry refer to our blends as simply ‘terpenes,’ they are actually a blend of several classes of organic chemical compounds,” Bonventre explained. He continued to say that terpenes can broadly describe monoterpenes and sesquiterpenes, but many of the compounds they work with are terpenes, esters, alcohols, ketones, lactones, thiols, and more. After that clarification, Bonventre went on to explain to us the three different types of terpenes.

Cannabis-derived “terpenes” (CDT) are chemical compounds extracted directly from cannabis trim or flower. Bonventre likes to refer to the compounds as a “soup” that contains compounds such as phytols that may have some residual plant material and chlorophyll, and possibly some flavonoids along with the terpenes, thiols, esters, alcohols, ketones, etc., depending on the extraction method used.

Botanically derived “terpenes” (BDT) are blends of aromatic compounds. According to Bonventre, it’s the impurities in BDT that bring about more fruity and citrus aromas. “The impurities in the different compounds, depending on what they are derived from, often contain complex essential oils that taste or smell like the plant they come from,” he explained. As an illustration, he said that Terpene Warehouse buys the sesquiterpene Valencene at 55-percent purity instead of 90-percent.

“Valencene is derived from valencia oranges and grapefruits, so when we get 55-percent pure valencene, we get a product that is packed with flavor and aroma, as opposed to 90-percent pure, which has much less aroma and flavor.”

Synthetic “terpenes” provide a product that has almost no impurities at all, except for the trace amounts left behind in the process of synthesizing the compound. Given what we know about purity and flavor, it makes sense that synthetic blends would not be very flavorful without flavoring additives.

However, Bonventre cautions against the use of synthetic terpenes.

“Most of the information out there from the FDA are in regards to synthetic versions of terpenes such as synthetic Myrcene (banned by the FDA), EthylAcrylate, Methyl Eugenol, Pulegone, Pyridine, and Benzophenone. All have been found to cause cancer in high concentrations,” according to FDA studies using lab rats.

For this reason, Bonventre and Terpene Warehouse have dedicated themselves to naturally derived ingredients.

“We strongly believe that if we as an industry are set on fighting for our rights and freedom to consume a plant that grows naturally, we should also demand that our terpenes are derived from natural sources, regardless of whether that be botanically derived or cannabis derived.”

Even though we talk about terpenes so often in this industry, Bonventre acknowledges we still have a lot to learn.

“These impurities are what we need to learn more about. As technology improves and GCMS and HPLC equipment become more advanced, we’ll be better equipped to dig

deep into what all these impurities are … With there still being so much left to learn, we need

to work together for the common goal of safety for all.”

A Tech Solution for Every Step of the Pre-Roll Process

Washington Governor Jay Inslee is proud of the state’s thriving technology sector. He shared on his website that 82 out of every 1,000 private sector employees in the state work in the tech industry, bringing in billions of revenue each year. One company adding to that atmosphere of innovation is technology solutions provider STM Canna.

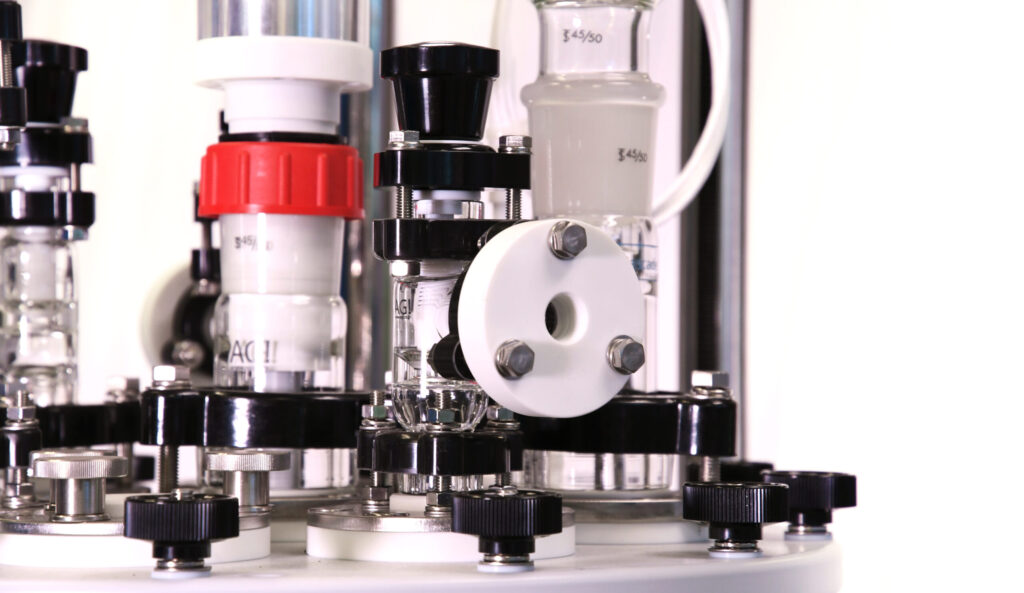

For the last five years, STM has been designing, engineering, and distributing eco-friendly cannabis processing equipment for commercial enterprises. Their pre-rolled joint filling machines and extraction production equipment are manufactured in the U.S using food-grade materials.

The company’s best-known innovation is the STM RocketBox, which produces 453 joints in 60 seconds. The machine can reportedly facilitate up to 500 times faster production. The Mini-RocketBox offers commercial grade pre-roll filling for smaller operations. It can create up to 143 pre-rolls in 45 seconds or less.

The STM Revolution 2.0 Industrial Grinder offers a consistent, homogenous grind with zero whipping or mashing. It can grind 15-30 pounds of dry flower per hour. The system also uses dual blades that act like scissors, creating clean, precision cuts. The Revolution also offers touch screen control for controlling the speed of the blade and auger. A closed loop feed system prevents clogs. The industrial grinder also has a 5-point safety system for added user confidence.

STM also offers a Mini-Revolution for small to medium sized operators. The company’s Sub-Zero Revolution Grinder offers the same efficiency as the Revolution, but is designed for cryogenically frozen flower.

STM is debuting some new, desperately needed pre-roll tech during 2021’s MJBizCon. While there are other brands offering pre-roll machines, there are few options for automated closing machines. STM’s new closing machine is filling that market gap with an industrial-grade solution. It can close up to 12 pre-rolls every second. The crown-style closure ensures each joint has a hand-packed smoke and feel.

Each STM machine comes with a 12-month parts and labor warranty. In just a few years, STM has gone from a small start up to serving some of the largest cannabis companies in the world. Their solutions are powering business in 38 states, Canada, the U.K., Israel, Australia, and South Africa. Their headquarters in Spokane, Washington is an ideal hub for maintaining those international connections and facilitating tech collaboration with many of the largest tech companies in the nation. It’s an ideal ecosystem for encouraging the type of innovation STM is known for producing.

Chief Marketing Officer Charles Warner is especially proud of their client services team, offering customer support by phone, email, and even video conferencing five days a week. “STM Canna has been on the leading edge of innovation in the cannabis equipment manufacturing space for over five years. It’s now recognized as a global leader in commercial cannabis processing,” said Warner.

Adapted Medical Technology is Creating a Safer Industry

“Among gardeners, enthusiasm and experience rarely exist in equal measure. The beginner dreams of home-grown bouquets and baskets of ripe fruit, the veteran of many seasons has learned to expect slugs, mildew, and frost.” — Roger Swain

In the past decade, the U.S. has started to change its view on cannabis. There are now 48 states with some form of legalized cannabis. Of those, 33 require mold, mildew, and bacterial testing. Washington State was an early adopter of adult-use consumption and has enacted several important consumer safety regulations over the last nine years.

While the state’s testing system is imperfect, catering more to medical users than adult-use when it comes to safety standards, it does regulate the presence of mycotoxins in all products. Some molds can produce toxic byproducts, known as mycotoxins. Rather than requiring total yeast and mold counts (TYMC), Washington tests for the toxins produced by mold and mildew. These mycotoxins include Salmonella and E. Coli, which the state has mandated cannot be present in any quantity in unprocessed plant material. The same is true of extracted or processed botanical products.

Tim Brady, marketing manager for Rad Source, emphasized the importance of mycotoxin tests. Rad Source is a microbial remediation technology company with a background in medical and life-sciences applications. Its technology has been used for cancer and cell research, infectious disease prevention, and now cannabis remediation. “Adult-use and even patients suffering from Alzheimer’s, ALS, HIV and AIDS, cancer … and many more medical conditions are dependent on the safety, quality, and reliable potency of their products,” said Brady.

Both indoor and outdoor plants are susceptible to mold and mildew. Contamination can also occur during harvest, trimming, drying, or curing. “Currently, 15-20% profit loss has been calculated as average in the industry for those not passing state-mandated testing,” said Brady.

While prevention is the best approach to avoiding mold, there are several forms of remediation available. Some methods degrade the flower, resulting in an undesirable final product and potential loss of profit. Medical technology adapted for the cannabis space, however, is proving to be highly-effective at destroying microbes in plant material.

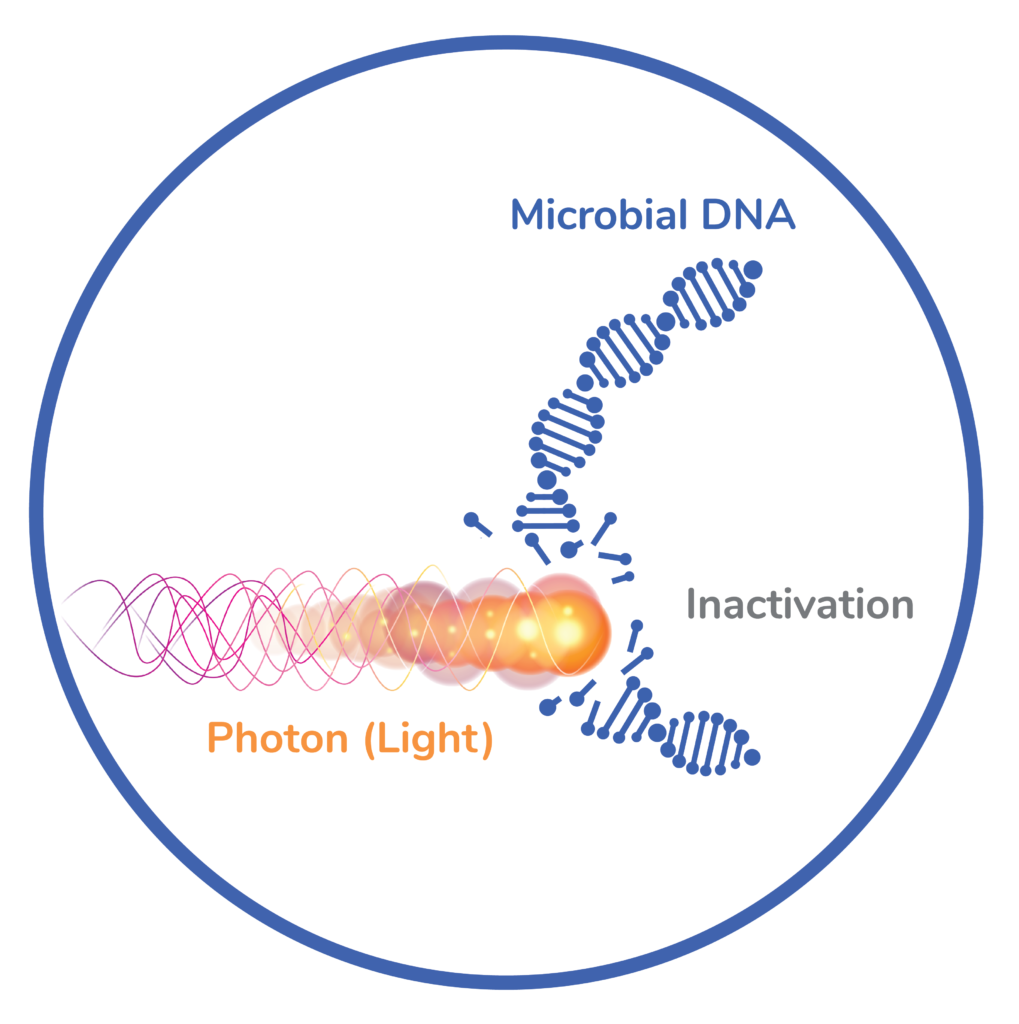

Brady said the compact nature of cannabis flower can limit the effectiveness of some forms of remediation, but doesn’t pose an issue for other treatments. “Photonic Decontamination produces short wavelength electromagnetic energy — better known as light — that is able to remediate microbial contamination with a 99.9% confidence level,” said Brady.

“Even in the most tightly-packed flowers, the light is able to penetrate the entire flower and destroy microbes at the DNA-level, meaning that it inactivates the reproduction of existing microbials.”

This cellular-level purity helps build consumer confidence. It also serves as an assurance to policymakers who are concerned with the safety and transparency of the industry. As Washington continues to refine its testing protocols and create a more consumer-friendly atmosphere for cannabis, effective remediation technologies will play an increasingly important role for producers.

How Cold Can You Go? A Look Inside Washington’s Leading Chiller Solution

What do the craft beer industry, the dairy industry, and now the extraction industry have in common? They all rely on low temperature refrigeration systems to successfully produce their products.

For years, Pro Refrigeration has been a leading chiller solution for both the North American craft beer and dairy industries. Over half of the medals awarded at the Great American Beer Fest 2018 were given to PROChiller customers.

In 2016, Pro’s CEO Jim VanderGiessen received a call from an extraction customer, Zach, who informed him that they were using the PROChiller (designed for breweries) to extract oil from cannabis.

“Zach had modified our system to operate 15-degrees Fahrenheit colder than we had ever tested before,” VanderGiessen said. “We quickly put our heads together and started designing systems for this market.”

“The only question any extractor ever asks a chiller guy is, ‘How cold can you go?’” VanderGiessen mused. “We then began to focus specifically on finding ways to make our equipment work better for the extraction market.”

Together with Zach, they set a couple of new targets. First, to design a lower temperature glycol-based coolant system to reach operating temperatures of minus 5-degrees F. Their second target aimed even lower, to hit coolant temperatures of negative 45-degrees F.

Soon, they released the M5 Series, which operated at minus 5-degrees F. This model allowed extractors to eliminate high operating costs of using dry ice. After continuous pushing and tinkering, they introduced the M45 Series, which brought their cooling number down to minus 45-degrees F.

“Dairy farmers and brewers understand the vital role of their chiller system,” VanderGiessen explained. “That has prepared us well for the extraction market. We started looking for more opportunities to help extractors improve their processes by delivering colder fluids at higher flow rates.”

One early extraction opportunity came from Double Delicious, one of the largest extraction processors in Washington state. Using an ultra-low temp freezer, Double D was spending five days cooling their ethanol after each extraction. Even after those five days, they still couldn’t get the ethanol below negative 30-degrees F.

As a solution, the team designed a two-stage stainless steel heat exchanger coupled with a pair of PROChillers: an M5 and an M45. The improved system dropped the ethanol from 70-degrees F to 5-degrees F in stage one, then below minus 40-degrees F in the second stage. The solution was so effective that it created other bottlenecks in the facility that needed to be remedied. Problem solvers at heart, ProRefrigeration jumped at the opportunity to further upgrade the recovery system so that the whole facility could run efficiently.

Now, VanderGiessen sees an open opportunity within the industry.

“Currently, for extraction chillers, you can find cheap Chinese imports or really expensive European imports,” he said. “The cheap imports are so affordable that customers simply throw them away instead of repairing them. The really expensive systems are specialized machines, and it’s very difficult to find people to service them.”

VanderGiessen’s hope is to fill in this gap and provide competitively priced chiller systems to this burgeoning industry. But, he’ll never lose sight of that key question: How cold can you go?

What Are Nanobubbles And Why Should You Care?

At 2,500 times smaller than a single grain of salt, it may be hard to believe that nanobubbles would have any significant effect on your cannabis plants. So you might be surprised to learn that nanobubbles could be the key to healthier cannabis. With a record amount of cannabis being grown each year, nanobubbles could hold the key to more efficient and productive cultivation. Enter Enrichment Systems, whose CEO Rex O’Neal explained to Cannabis & Tech Today the importance of their work and nanobubbles.

What is a Dissolved Oxygen System?

In August 2021, Enrichment Systems LLC, launched its P-150 Dissolved Oxygen System. “The P-150 Dissolved Oxygen System is the lowest priced and most effective dissolved oxygen solution available in the cannabis market,” says O’Neal. “It is capable of

increasing dissolved oxygen levels 500-600%.”

Understanding Dissolved Oxygen

Most water sources typically have 0-7 ppm of dissolved oxygen, while cannabis thrives at

20-25ppm of dissolved oxygen at the irrigation emitter. Because irrigation water can travel through hundreds of feet of irrigation line, including passing through pumps and fertilizer injectors, it is most beneficial to achieve close to 40+ppm dissolved oxygen at the reservoir to reach 20ppm dissolved oxygen at the plant. Enrichment Systems P-150 Dissolved Oxygen System can achieve 40+ppm at the reservoir due to its high throughput pump and efficient nanobubble generator.

Why Should I Care about Nanobubbles?

“Nanobubbles,” more frequently referred to as “ultra-fine bubbles,” in scientific literature, are gas bubbles no larger than .1 micron. Nanobubbles display very unusual properties in that they are not physically buoyant and therefore remain in suspension for long periods, up to weeks in some instances. Airstones and bubblers do very little to increase dissolved oxygen levels.

Dramatic Improvement in Plant Growth and Health

Steven Lipton, Director of Operations of The Flower Shop in Boulder, Colorado, has experimented with the Enrichment Systems P-150 Dissolved Oxygen System and has the following to say: “My preliminary experience with this system has been unqualified positive. I see increased leaf count, stem circumference, and root development very early in veg. EC levels are significantly lower, leading me to believe plants are uptaking nutrients more efficiently. Plants are bigger, stronger and healthier, and remain stronger at every stage of growth.”

So there you have it. The key to your next grow operation may be your tiniest asset yet.

What’s in Your Fertilizer? Emerald Harvest’s Guide to Nutrients

In early 2021, Washington legislators attempted to pass a bill that would make it legal for consumers to grow cannabis at home. While many states allow this, Washington state does not. With the increased interest in homegrown cannabis, Cannabis & Tech Today sat down with Dan Mair, Product Specialist of Emerald Harvest, to discuss plant nutrients and supplements.

With so many different nutrient and supplement options, and labels with mountains of information, how is one supposed to decipher what their plants need?

“If even one essential plant nutrient is deficient, yields will suffer.” This bold statement from Mair describes the phenomenon “Law of the minimum,” which means that plants need at least a minimum amount of every essential nutrient in order to flourish. “It doesn’t matter if a plant gets more than enough of every essential nutrient but one,” Mair explained, “if even one essential nutrient falls beneath its minimum, it will suffer a deficiency, with yield and crop quality leaking away.”

In addition to hydrogen, oxygen, and carbon—essential non-mineral nutrients that plants take from the air and water — there are 14 essential mineral nutrients:

• The primary macronutrients: nitrogen, phosphorous, and potassium

• The secondary macronutrients: calcium, magnesium, and sulfur

• The eight micronutrients: iron, boron, zinc, manganese, copper, nickel, molybdenum

Different species will have different appetites for different nutrients during different times of their life cycles. Therefore, nutrients need to be applied in the right concentrations and formulated in the right ratios at the right times. According to Emerald Harvest’s own analysis, here is the breakdown of essential plant nutrients in the cannabis plant:

• Nitrogen: 37.7%

• Potassium: 28.5%

• Calcium: 26.1%

• Phosphorous: 3.4%

• Magnesium: 3.4%

• Sulfur: 0.45%

• Iron: 0.25%

• Boron: 0.08%

• Zinc: 0.04%

• Manganese: 0.03%

• Copper: 0.01%

• Nickel: 0.004%

• Molybdenum: 0.003%

As you can see, the macronutrients outweigh micronutrients by a huge margin. However, don’t doubt the importance of any single micronutrient. Deficiency in just one micronutrient can still cause lower crop quality.

When it comes to fertilizers, there are a few other ingredients outside of essential nutrients that can be a benefit to the plant. What Mair refers to as “non-plant-food ingredients” is jargon to indicate nutrients that are beneficial, but not necessarily essential, to plants, as well as plant-beneficial compounds not found on the periodic table. While base nutrients must include all of the essential nutrients, supplements often focus on these extras.

Humic acid is a natural soil conditioner that forms chelate complexes with essential nutrients such as magnesium, calcium, and iron.

Vitamin B1 (thiamine) activates a “whole plant” immune response, bringing out qualities that humans prize, and may encourage root growth in young plants.

Cane sugar (or carbohydrates) is another beneficial non-plant-food ingredient that acts as a microbe food.

According to Mair, it’s the knowledge of these important nutrients and ingredients that will make your grow successful. “There is no genie in the bottle: no magic, just science,” he concluded. “Nutrient companies that imply that there is something supernaturally superior about their products need to dial the marketing hype down a notch … Nutrients are nutrients. But to be successful, you need to choose the right nutrients with the right formulations. They’re not magic potions for your plants.”

A Quick Cure for Preserving Crops

New tech delivers perfectly dried buds in less than 14 hours.

The western side of Washington is one of the most humid places in the country. While it may not feel humid due to the temperate climate, persistent rainfall keeps the air damp. That moisture can make it difficult to properly dry and cure flower. Powdery mildew and mold are pervasive problems for farmers in the Evergreen State.

An innovative approach gaining a foothold across the U.S. and Canada is Cryo Curing. Michigan-based Cryo Cure has reimagined traditional freeze drying and is using their patent-pending tech and U.S.-made machinery to advance the industry. CEO and co-founder Tracee McAfee explains, “Commercial Freeze dryers are designed to remove all moisture from whatever it is that is being dried. For a smokable flower that’s not good because when you’re drying it out like that, you’ve removed a lot of the valuable terpenes and it’s going to be dry as dust and not smoke very well. What we’ve done has taken that out of the equation of freeze drying and modified it with our ‘recipe’ for smokable flower that is full of terpenes, at the desired moisture content and water activity level. This creates the ultimate consumption experience while improving the bottom line for cultivators and processors.”

Washington’s Olympic Peninsula is one of the rainiest places in the world. While that’s great for cutting costs on irrigation, it puts outdoor growers at higher risk of botrytis, or bud rot. Bud rot can occur during the growing process or during drying. These outbreaks can result in thousands or even millions of dollars in crop loss. Cryo Cure’s freeze drying process mitigates the problem and is an affordable long-term solution that takes buds from stalk to smoke in just hours. Their smaller CC360 machine can process up to 100 wet pounds at a time and dry a batch in 12- 14 hours. Their largest machine, CC720, holds up to 1,200 wet pounds at a time.

McAfee said this method also preserves terpenes more effectively than traditional drying. “We’re able to capture and preserve a terpene called carene; it’s a fragile mono terpene that normally dissipates during traditional drying methods. We’ve suspended that degradation with our Cryo Cure process.”

McAfee understands people need to see, smell, and experience the results themselves. They’re offering live demonstrations as well as case studies and independent lab results on their website. “Unfortunately, there’s a lot of snake oil in our industry right now, so people really want to feel confident in what they are integrating into their operations. We back up everything we do with consistency, science, data, education, and proven results,” said McAfee.

Demand Grows for STEM Talent in the Evergreen State

Lush rainforests, towering mountains, and legal adult-use cannabis are just a few reasons to love Washington. But this state has more to offer than scenic beauty. It’s also carving out a niche as a national leader in STEM.

The U.S. Chamber of Commerce Foundation found Washington has the second highest concentration of STEM jobs in the country. It’s also fourth in the nation’s “New Economy” index for innovation and entrepreneurship as ranked by the Information Technology and Innovation Foundation. So what does this mean for cannabis? Ample opportunities for tech job seekers.

Many of the nation’s cannabis companies are built around STEM skills. Cascade Sciences, a pharmaceutical-grade processing equipment manufacturer, joined the cannabis space to meet the demand for science-based manufacturing solutions. The woman-owned business has been providing laboratory testing and processing solutions for 30 years.

“Cascade cut its teeth in STEM fields such as aerospace, pharmaceutical, technology, and academia. Those industries require sophisticated technology that can perform day-in-day-out and offer repeatability, which is why our vacuum ovens caught the attention of cannabis producers,” said Rebecca Allen-Tapp, director of business development for Cascade Sciences.

As an Oregon-based company, Cascade Sciences was geographically primed to meet the needs of the Washington adult-use market. When the recreational industry opened up, the company was able to help clients set up new labs and start optimizing their processes for the developing industry. It was a smart move. The state earned $172 million more from cannabis sales than liquor sales in 2019. Further, the Liquor and Cannabis Control Board reported a total of $395.5 million in legal cannabis revenue that year.

The industry’s growth will coincide with a boom in STEM jobs.

Washington state is already home to huge tech employers like Amazon and Microsoft. This can largely be attributed to The University of Washington computer science program, ranked sixth in the nation by U.S. News. It’s a region that understands the value of technical skills in creating a robust economy.

To continue its legacy as a “tech zone,” Washington’s universities are adding new areas of study. Western Washington University, for example, added four new certificate programs in 2021 focused on career preparation and skills development for the cannabis industry.

Allen-Tapp said this is one area where she’s most excited to see continued growth. “I would like to see the cannabis sector evolve to focus more on education, procedures, collaboration, and an emphasis on testing.” Those elements are vital to create a more transparent industry, and one that’s ultimately able to transition to federal legalization. When cannabis is legal on a national scale, states training their students to excel in STEM will have the advantage.

“There are many areas within the cannabis industry that having a background in STEM would be beneficial — and for processing or analytical environments it is nearly crucial,” said Allen-Tapp.

Managing an IT Ecosystem

Entrepreneurs are masters of multitasking. While wearing every hat isn’t ideal, it’s part of the gig. Technology integration is stepping up to help, but managing the technology can be a full-time job in itself.

For Washingtonians, being tech-savvy is nearly a requirement for residency. The state’s tech sector employed 246,000 workers in 2019, as reported by the Washington State Wire. With so many tech professionals in the area, there are ample resources for business owners looking to bring in more automation.

Building an IT Strategy

Stephen Arndt, president of Cannabis Technology Partners, said working with an IT management company early on is crucial. “The sooner we get involved with a client, the easier it is to prevent bad technology decisions that are costly to undo or redo.” His company offers free consultations so business owners can better understand their needs and the costs associated with implementing solutions.

From those discussions, Arndt builds an IT strategy to determine how much technology (servers, computers, etc.) a business needs. “Our goal is to form a partnership with our clients, to maximize the efficiency and productivity of their business, and to enable them to achieve a competitive edge by leveraging current technology,” said Arndt. There are so many areas to automate now that operators may have to let their budget decide where to focus. Compliance is a good place to start.

You’ve installed surveillance systems and have control over who can access what, but is that the end of your compliance strategy? “We’ve talked to so many companies that don’t have any mechanism to ensure the system is functioning on a day-to-day basis,” said Arndt. Finding a partner who offers 24/7 compliance monitoring ensures the tech is working and everything is in line with evolving regulations.

Daily Operations

Operators should have data management covering everything from inventory to customer retention. As ever, it sounds easier than it is.

“We realize ultimately what companies need is hassle-free IT that allows them to accomplish their daily tasks, meet deadlines, input data, and engage efficiently and intentionally with their client base,” said Arndt. Comprehensive IT could also include ensuring internet connectivity (even in remote areas), networking between multiple sites, or integrating disparate applications for better efficiency.

Security Solutions

Data integrity, computer viruses, hackers, and tech failures are major concerns. Moving to a cloud-based storage solution can help. “If you haven’t started a move to the cloud, you are behind,” said Arndt.

“This business model, especially with regards to security and compliance, is the only one that can move fast enough to keep with the threats in today’s world.”

Planning for Success

IT management is a foundational element for building a successful operation. As Arndt pointed out, “It takes a team to stay on top of all the risks and even then, things happen.” Working with qualified professionals from the ground up helps ensure those issues arise less often, and when they do, there’s a plan in place to resolve them.

Time for a Change: Solutions for Cost-Effective Edible Manufacturing

Edibles manufacturers face a host of challenges ensuring product quality and stability through the supply chain. In heated conditions, like in a truck cargo bay during transport, cannabinoids can leach out of packaged products before they get to their destination. Additionally, over time, in traditional edible manufacturing the distillate in the final product can crystalize, which can be accelerated by cold temperatures. Supply chain stability is a persistent problem in the edibles space. How do you create a shelf stable product that travels well despite changes in temperature?

The Washington marketplace can be especially vulnerable to supply chain and distribution problems because of its diverse geography. While transporting goods across the state, a truck might travel through rain forests into dry canyons and high into the Cascade Mountains before hitting a shelf. Advances in technology and processing now solve these challenges.

Chef Ron Silver, Founder and Chief Creative Officer for Azuca, applied his knowledge of the culinary arts to create more shelf-stable formulas for cannabis edibles. “I started to see new and innovative ways to use culinary techniques to bring out the best in the cannabis plant. I spent a lot of time in the kitchen, developing what eventually became our Azuca TiME INFUSION technology, and in the years since, have watched it transform the cannabis edibles industry,” said Silver.

The acronym TiME stands for Thermodynamic individual Molecular Encapsulation. The process not only helps stabilize the cannabis molecules within the product, it also helps the body to process them more efficiently. “It’s a process that makes ingestible cannabinoid particles smaller and water friendly, enabling faster uptake. This process begins immediately in the mouth, avoiding the liver where cannabinoids are degraded and absorption is slowed. That’s how we are able to cut that traditional 90 minutes [for edible activation] down to less than 15 minutes,” said Silver.

One unique aspect of Azuca’s process is that it’s easily available to manufacturers. Washington State cannabis companies can take advantage of TiME INFUSION in their own production facilities. “A key benefit to integrating this technology into an existing edibles production process is that it doesn’t require burdensome training or large capital investment, making the adoption seamless and cost-effective,” said Kim Rael, President and CEO of Azuca.

Edible makers also face “transfer loss.” The stickiness of distillate makes it cling to mixing equipment and anything it touches, causing transfer loss. Transfer waste costs manufacturers an average cannabinoid loss of 15-20%. Azuca’s processes reduce transfer and potency loss in edibles by up to 65% according to their white paper study Stability and Waste Solutions for Edible Manufacturers.

These tech advancements are exciting for edibles brands and end customers. “Our consumers no longer have to play the guessing game when it comes to onset time and dosing. Our infusions taste great, and we’re tackling manufacturing challenges to minimize waste and ensure the longest shelf life possible. It all comes down to science,” said Silver.

Sustainable Packaging in 4 Steps

Packaging is so common these days that it’s nearly invisible. Everything comes in some sort of package — so much so that we often mindlessly throw them away without really thinking about where the packaging came from or where it is going.

With packaging as prolific as it is, it’s crucial consumers and companies alike start to question the source of their packaging and how it can be made more sustainable. According to Ponder Seattle, there are nearly twice as many producers/processors as there are dispensaries in Washington state, resulting in competition for limited shelf space. Sustainable packaging might be a key to standing out.

Alpha Packaging is a manufacturer of bottles and jars for the cannabis industry and others. All of their packaging is manufactured with sustainability in mind, and their solutions can be broken into four categories.

100% Recycled Content

First, recycling is one of the most common sustainability strategies. While it’s important for individual consumers to participate in recycling, it can have a much bigger impact when utilized by large manufacturers. For instance, Alpha Packaging makes their bottles and jars with up to 100% post-consumer resin (PCR). By utilizing recycled HDPE and PET resins, Alpha Packaging provides brand owners a sustainable packaging solution that performs just as well as “virgin” plastic.

Recyclable Resins

Recycling as a consumer can be tricky. Figuring out what products are recyclable in your personal community recycling program is a difficult task. To clear up confusion, many brands use the phrase “recycle-ready,” which means their packaging is accepted by most community recycling programs. It also means there is a viable recycling stream that can capture the resin, giving it a useful second life. In Alpha’s case, 98% of the bottles they manufacture are mono-layer PET or HDPE plastic, which are SPI codes 1 and 2 respectively, and are the most widely recycled plastics in the world.

Plant-based Resins

Of course, recycled content isn’t the only option when manufacturing packaging. Plastics made from plants, also known as “bioresins,” reduce or eliminate the amount of petrochemicals required to make resin. As an example, in the case of plant-based HDPE, Alpha has a source for an HDPE bioresin that is made entirely from sugar cane byproduct. The bio-HDPE is chemically identical to traditional HDPE, but the feedstock is sugar cane instead of petroleum. In the case of PET, the most common plant-based formulations use renewable plant resources to replace the monoethylene glycol (MEG) component of polyethylene terephthalate.

Lightweighting

For both sustainable and financial reasons, the goal for any brand owner should be to minimize packaging as much as possible while still ensuring their products are protected. Light-weighting primary packaging is a smart way to reduce the amount of raw materials being used for each package. In practice, Alpha’s Design & Engineering teams work with their customers to find the optimal gram weight that balances performance and sustainability, working to find the lightest weight possible. In some cases, they’ve been able to reduce the total gram weight of a bottle by up to 29% without negative effects on performance.

Originally published in the fall 2021 issue available here.