Cannabis recalls are soaring across the U.S., creating an inflection point for brands facing

intense scrutiny. In California, recalls surged to 23 cases in just the first half of 2024—almost

triple the previous two years combined. Missouri issued two massive recalls this year affecting

over 135,000 products, while Maine recently pulled flower and pre-rolls off shelves due to

contamination.

Takeaways for Cannabis Brands

With the rise in recalls, the message is clear: cannabis brands must prepare. Here’s how brands

can move forward following a recall.

- Learn from the Experience – Analyze the recall circumstances, identifying lapses in quality control, testing protocols, or tracking procedures. A systematic review reveals patterns in contamination sources or production stages where oversights occur.

- Invest in Proactive Measures – Recalls are preventable. Investing in advanced cannabis decontamination solutions, like XRpure’s XR16, can significantly reduce risks. These solutions neutralize common contaminants like mold, yeast, and pesticides without altering product quality.

- Build Resilience through Safety and Transparency – Transparency can turn a recall into a reputation-building moment. Brands that prioritize consumer safety and back it up with transparency can transform setbacks into long-term marketplace resilience.

Understanding the Impact of a Cannabis Recall

The consequences of a recall are severe for cannabis brands. Financially, recalls can mean

significant losses due to halted sales, disposal costs, and fines. Reputationally, recalls erode

consumer trust, which is challenging to rebuild in a competitive market. Operationally, brands

must contend with inventory recalls, warehouse adjustments, and restructured distribution—all

demanding resources and careful coordination.

Post-Recall Steps

It’s all about swift, organized action. Start by promptly notifying regulatory authorities and

meeting all legal compliance steps. Document every communication and follow directives

carefully to avoid penalties and demonstrate accountability.

Next, inform retailers, distributors, and partners, giving them clear instructions for handling

recalled products. This will maintain supply chain trust and ensure that affected products are

removed from the market.

Finally, address your customers directly. Develop a communication strategy, outline resolution

steps, and affirm your commitment to safety. Transparency is critical here—open communication

protects your reputation and builds consumer trust.

Conducting a Root Cause Analysis

After a recall, examine every production stage to identify where contamination or errors

occurred. Isolating the root cause gives brands a roadmap toward implementing solutions to

prevent future issues.

Strength Quality Control and Compliance Protocols

Begin with Quality Assurance (QA) steps:

● Establish rigorous testing protocols

● Regularly audit production stages

● Maintain thorough documentation for every batch

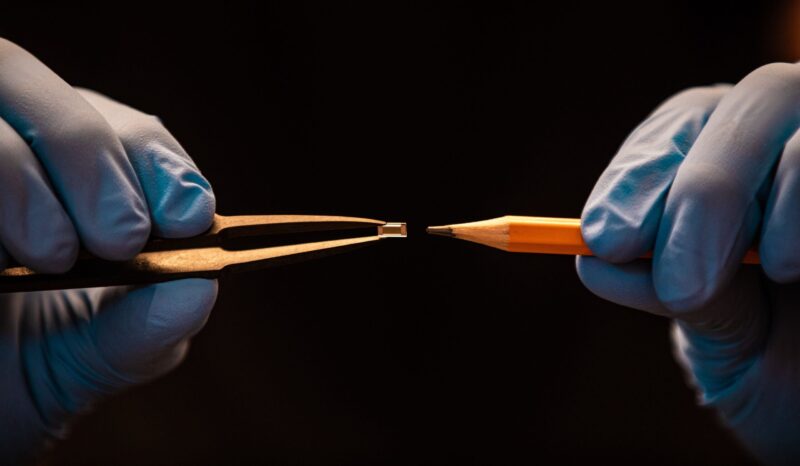

Integrate advanced cannabis decontamination solutions like those from XRpure to tackle any

possible contaminants. Also, enhance your testing and product monitoring practices. Implement

routine spot-checks, invest in comprehensive testing equipment, and closely monitor

compliance metrics.

Rebuilding Trust with Customers and Partners

Craft a transparent recall response campaign that explains the recall, outlines corrective

actions, and reaffirms your commitment to product safety. Leverage social media and PR

channels to address consumer concerns, provide updates, and share your ongoing safety

efforts. Consider offering support to affected customers through refunds, discounts, or

educational resources on product safety. Turn a challenging situation into an opportunity to

reinforce loyalty.

Creating a Proactive Recall Prevention Plan

A proactive recall prevention plan starts with a comprehensive preparedness strategy that

includes defined roles, communication protocols, and procedures for addressing product issues.

Other pieces of the plan include regular audits and quality assessments throughout the

production process.

Then, there are post-harvest decontamination solutions, such as those delivered by XRpure’s

advanced X-ray technology. XRpure reduces microbial contaminants like mold and bacteria

without altering product quality.

Connect with XRpure today and get back on track post-recall.