Though disposable gloves are a staple in many stages of cannabis cultivation and processing, most wearers never give a second thought to the possibility of glove cross-contamination that could jeopardize their products.

But, as the evidence mounts, it’s a concern that likely requires more than just a passing glance. At stake is the health and safety of cannabis workers, consumers, and costly product recalls that not only affect bottom-line financials but also the very reputation of the company itself.

Cannabis recall due to glove contamination has happened before, and the possibility of future recalls continues to be a threat to the industry – as well as its consumers.

What Cross-Contamination Testing Revealed

When procurement departments purchase disposable gloves, the price is often the primary concern. But unless you’re careful in how you source and select your single-use gloves, you could be in for a big surprise.

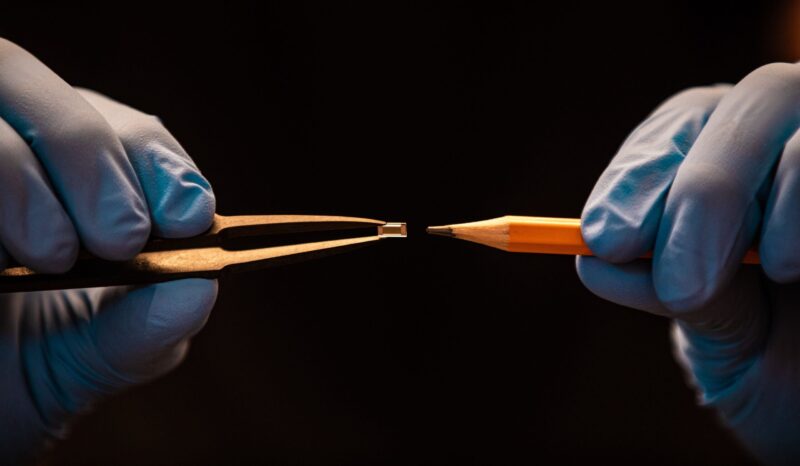

The results of a recent five-year study, which included 26 different brands and over 2,800 new and unused gloves tested, revealed an alarming level of contamination.

The third-party independent testing and analysis showed fecal indicators on up to 50% of the gloves that were tested, as well as many pathogens and fungi including E Coli, Listeria and Aspergillus.

While any of these threats are capable of causing cross-contamination and recalls within cannabis-related supply chains, you may be wondering … how is this even possible?

How It Begins…

The threat of cross-contamination in disposable gloves begins during the manufacturing process. Previous incidents and recalls have been traced back to inadequate process controls, unsanitary factories, contaminated water sources, and lax oversight.

Then there’s the low level of import compliance under regulation from enforcement agencies.

In previous incidents, the FDA singled out many inadequate process controls during glove manufacturing, which subsequently led to gloves being contaminated with harmful fungi such as Aspergillus sp. and Fusarium sp.

These can lead to sickness and even death among the immunocompromised.

The Growing Popularity of Cannabis-Related Products

According to the latest figures, there are approximately 21 U.S. states and/or territories where recreational cannabis use is now legal, up from only two just a decade ago.

As the popularity of cannabis and its related product lines continues to expand across the country, the risk of cross-contamination rises along with it. If and when product recalls occur, there is no bearing on the size of the manufacturer, as the risk is present across the board.

But how do we as an industry solve the problem of this increasing threat of bacterial, fungal, or allergen-related contamination? A good start would be to tighten glove import compliance standards.

A Glove Marketplace in Turmoil

As one might expect, the global pandemic nearly doubled the demand for single-use gloves. Sensing an opportunity, new manufacturers and traders with little to no industry experience and with a sales commission incentive, flooded the market with counterfeit and poor quality gloves.

Though the demand was through the roof, the industry did not respond in a manner befitting high standards. At one point, two top global glove suppliers were even banned from importing products into the U.S. due to labor violations in an expose that made front-page headlines on CNN.

It became a lesson learned. Though you may save a few dollars on the front end, you could also pay dearly on the other side.

Solutions to Consider

A review of acceptable manufacturing standards and in-depth quality control measures can help prevent the threat of cross-contamination and recalls, while protecting the health of cannabis workers and consumers.

Regulatory agencies could explore higher standards, thereby making third-party testing, product traceability, and routine product audits much more commonplace than they are today.

Compliance should begin with the manufacturing process itself, where sourced raw materials that make up glove composition can be authenticated.

Disposable gloves and other PPE should be guaranteed safe from chemicals, toxins, and the threat of microbial contaminants.

Cost, of course, will always be a factor, but sourcing high-quality gloves for wet-trimming, dry-trimming, pre-harvest trimming, and other associated cannabis-related processing, will ensure workforces don’t need to replace gloves that rip and tear too easily.

When the time comes to source disposable gloves, those responsible should always seek a reputable supplier – one that displays clear ownership origins and boasts of their own high-quality control measures.

It’s also quite acceptable to inquire about trial offers, factory audits, and subsequent HACCP compliance certifications. Done right, these comprehensive steps can go a long way in guarding against fungal, microbial, and even pesticide-related cannabis cross-contamination.

But what the disposable glove industry really needs, above all else, are policies that reflect adherence to our product’s consistency, safety, and performance.

Anything less will leave the industry exposed to the ongoing threat of cross-contamination, which not only jeopardizes the health and safety of cannabis companies and their workforce, but also its growing customer base.

Author

-

Steve Ardagh, “The Glove Guy,” is the founder and CEO of Eagle Protect, a disposable glove supplier dedicated to the responsible sourcing of quality products that ensure customer safety and impact reduction, ultimately mitigating customers’ risk. Eagle Protect is the only global PPE supplier that is a Certified B Corp, a designation that a business has met the highest standards of verified performance, accountability, and transparency. He can be reached at steve@eagleprotect.com.