For brands that have built their identity around the concept of craft cannabis, the conversation of whether or not to automate comes with a lot of questions. What will it do to our products? What will consumers say if they learn our products are manufactured using automated processes? How will this impact our reputation?

Brands fear not! While these are important considerations, the reality is that automation is not the boogeyman that some believe it is. Producing quality products and preserving craftsmanship can still happen when employing automated processes.

Consumers have no expectation that items purchased in a commercial setting are made entirely by hand. So, the question then becomes to what degree can you automate while still preserving craftsmanship?

First, let’s discuss what craft means. While there are no specific parameters or criteria, most consumers will define craft products as having higher quality than budget brands. The concept of craft is often connected to a business’s scale, with small businesses being able to retain that label while large MSOs can not.

For some, it can mean local, unique, or differentiated from more “mainstream” offerings. For others, craft means taking a small batch approach to production and attention to detail. And craftsmanship is the skill needed to produce excellent products defined by some or all of these parameters.

The idea that craftsmanship only exists when products are entirely created by hand is not only false, but also unrealistic in a commercial setting. It’s not even an expectation on the part of consumers.

Nobody walks into a grocery store, even a local or organically-focused one, and has any expectation that the products they find are made by hand. That doesn’t mean you can’t find products in those stores that are characterized by the high level of craftsmanship needed to produce them.

Automated pre-roll machines are simply tools; without a skilled operator, they will produce poor-quality products. It’s up to the operator to manipulate the machine and its inputs (flower, paper, tip/crutch) to create a quality pre-roll.

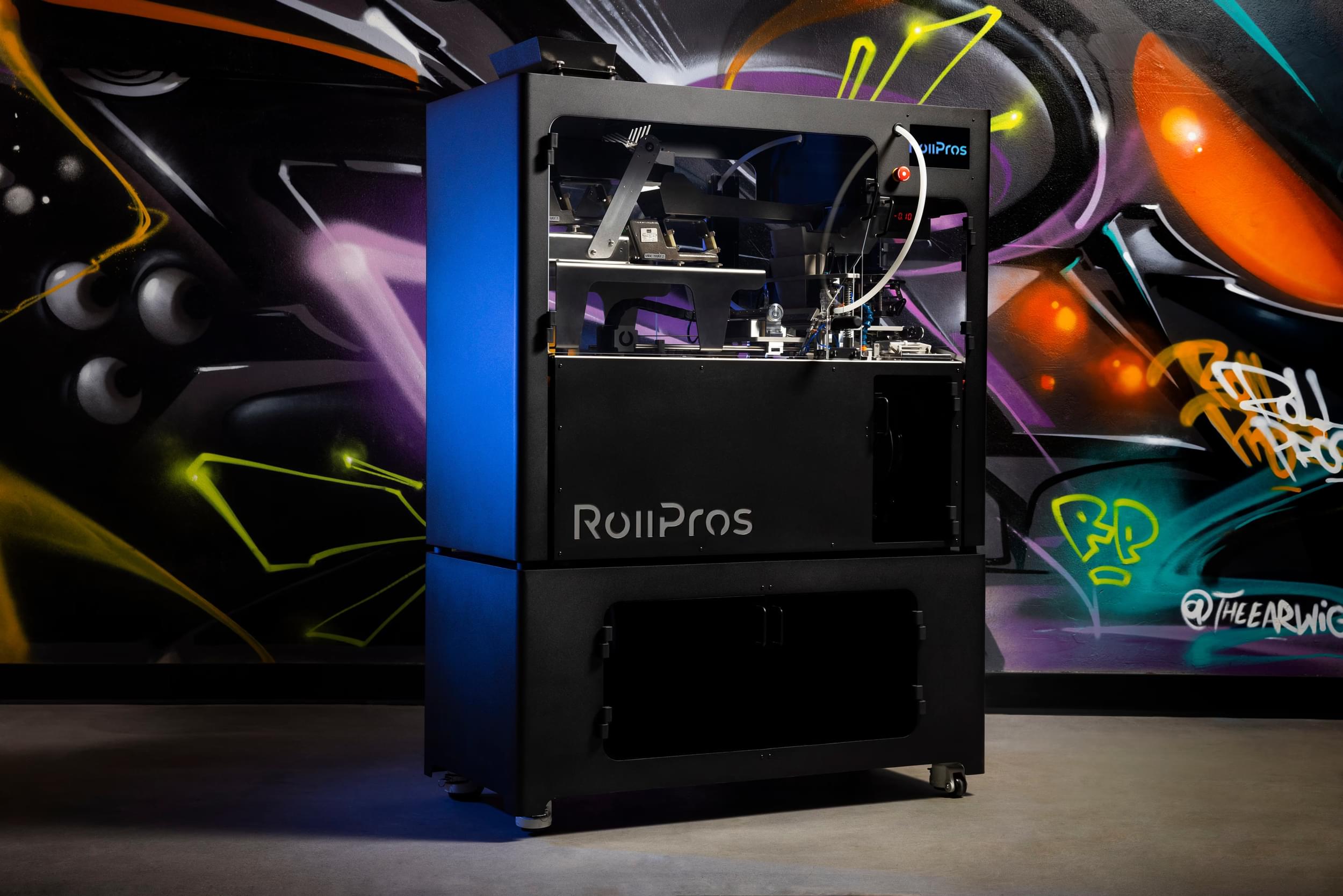

In the example of our product, the RollPros Blackbird, it’s not like a microwave. You can’t simply dump a bucket of cannabis into the hopper and expect perfect pre-rolls to fall out the other end. The Blackbird features numerous settings that can be manipulated to create whatever product the operator wants based on whatever specs they determine.

The grind size and homogeneity of the flower must be taken into consideration. The moisture content needs to be just right. If the product is going to be infused, then that process needs to be dialed in. What paper type are you using? What size and weight is your target? Does it draw correctly, not too loose and not too tight? Are you using a paper crutch? Or wood, ceramic, glass, or plastic?

Talented and skilled operators (aka craftsmen) use the Blackbird to create exceptional products. A poorly trained or disinterested operator has no chance of doing the same. Craftsmanship is about attention to detail and thoughtful consideration of every component of the pre-roll and every step of the manufacturing process.

Automation of the pre-roll space is an opportunity for manufacturers to free themselves of some of the many constraints of a more manual production process. Instead of the monotonous task of hand-rolling or operating a semi-automated machine like a knock box, they have the ability to focus on and experiment with other parts of the process.

They can develop new manufacturing and customization “recipes” for each strain or product line. They can focus on dialing in and manipulating all the variables and settings, like roll tension and vibration. They can experiment with different inputs, grind settings, and moisture content.

Operators that are successful with the Blackbird are true artisans, meticulously analyzing every component of their creations. It isn’t just us saying this…our customers say it too. “The Blackbird is an artisan machine that gets its best results when operated by an artisan,” according to Benson Arbor CEO Noah Levine.

Have you ever heard anyone say that about automation equipment? Especially at scale? (The Blackbird produces approximately 750 joints per hour and isn’t a good fit for a small-scale operation).

The Blackbird doesn’t eliminate the craftsmanship that goes into every joint it produces. There is still a world of tweaks, customization, and experimentation to explore, all with the singular goal of creating exceptional pre-rolled joints. It gives the operator more control than they would ever have by hand to create the products their customers want.

It frees up the operator to focus more on the details that really matter. Many joint smokers will always prefer joints they roll themselves. But for those that value convenience, scaled pre-roll production doesn’t have to mean a poor-quality product. Whether rolled by hand or on a machine, it takes a talented craftsman to create an outstanding pre-roll and smoking experience for their customers.

Authors

-

Kyle Loucks is the founder and CEO of RollPros (www.rollpros.com). Since 2020, Kyle and his team at RollPros have helped cannabis companies succeed by providing them with industry-leading technology that creates premium-quality pre-rolls. Blackbird-manufactured pre-rolls build consumer loyalty, reduce overhead, boost efficiencies, and eliminate tedious manual labor processes.

Prior to RollPros, Kyle held various lead engineering and technical roles for companies ranging from innovative medical device startups to tech giants like Hewlett-Packard and Georgia Pacific. He also played a key role in developing optics hardware for Facebook's Oculus VR system.

-