For much of the past decade, cannabis vaporization has lived in an uncomfortable middle ground. It promised a cleaner alternative to combustion, fewer odors, less ritual, and greater discretion, yet often delivered an uneven experience. Burnt hits, clogged cartridges, fading flavor, and lingering questions about what was happening inside the device undermined confidence among both recreational consumers and medical patients.

As the cannabis market matures, that imbalance is beginning to correct. Vaporizer hardware, long treated as a commodity, is undergoing a technical reset driven less by novelty and more by engineering discipline. The next wave of innovation is focused on aerosol science, materials safety, and repeatable performance, areas that have shaped consumer trust in adjacent industries such as food, pharmaceuticals, and regulated nicotine.

Few companies illustrate that shift more clearly than Greentank Technologies.

When Hardware Became the Bottleneck

Greentank Technologies was founded nine years ago in Toronto, at a moment when legal cannabis in Canada was accelerating faster than the tools designed to deliver it. Early vape hardware was often repurposed from nicotine devices or sourced with minimal oversight, ill-suited for the wide variability of cannabis oils.

“Greentank has been around for nine years, originally set up because of quality, consistency challenges as the cannabis industry was beginning its early stages in Canada,” said Chris Gemmell, Greentank’s chief product and innovation officer. “Technology at the time wasn’t particularly robust or reliable.”

Cannabis concentrates vary dramatically in viscosity, terpene composition, and formulation. Those differences matter. When oil interacts unpredictably with heating elements, the result is inconsistent aerosol production, degraded flavor, and device failure. For consumers, the experience feels unreliable. For manufacturers and regulators, it raises deeper concerns around safety and repeatability.

Greentank’s founders, Corey and Dustin Koffler, responded by studying the supply chain itself, examining how products were manufactured and how different technologies behaved in real-world use. That work led the company to establish licensed testing facilities under Health Canada and to anchor its product development around a deceptively simple idea known internally as the oil-coil balance.

“To keep it simple, Dustin often talks about the oil-coil balance,” Gemmell said. “But, to unpack that, we are focused on the optimum way the oil and the hardware come together to deliver a high-quality, consistent, safe, and pleasurable user experience.”

Rethinking How Vapor is Made

Traditional vaporizer designs rely on absorbent heating elements. Early devices used wire coils wrapped in cotton. Later iterations introduced porous ceramics designed to soak up oil and draw it toward a heated surface. These technologies helped popularize vaping, but they come with inherent limitations.

“With anything where you have this sponge concept going on, what you’re doing is heating up, cooling down, heating up, cooling down the same bit of liquid that is stuck within that system,” Gemmell said. “From a consumer experience and toxicology perspective, that’s not optimal.”

Repeated reheating degrades flavor and can lead to buildup that blocks pores and produces burnt notes late in a cartridge’s life. The inconsistency is not only sensory, but structural. Ceramic heaters are not uniform at a microscopic level, meaning no two devices behave exactly the same.

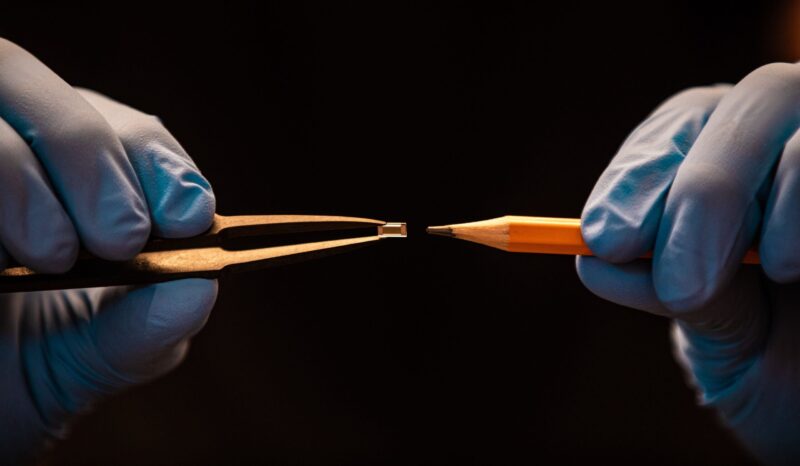

Greentank’s response was not an incremental improvement, but a redesign. Its Quantum Vape platform replaces absorbent heating elements with a micro-engineered substrate with more than 3,000 precision channels. Rather than storing oil within the heater, the system pulls liquid through the chip for each draw and aerosolizes it almost instantly.

“Every time you take a puff, the liquid spends a fraction of a second inside the chip as it’s pumped through and atomized,” Gemmell said. “You’re not reheating the same thing again and again.”

The heating surface is constructed using inert, biocompatible metals rather than nickel or chromium alloys. From an engineering standpoint, the benefits include reduced carbonyls yields, fewer harmful and potential harmful constituents (HPHC), and markedly improved consistency from the first draw to the last.

Consistency as a Consumer Value

While toxicology and materials science are central to the design, Gemmell is clear that consumers rarely evaluate hardware through a technical lens. They judge it by whether it works.

“We are a very consumer-centric company,” he said. “When a consumer goes in and buys a product, I want them to have a hassle-free experience. No clogs, no leaks, no burnt hits. They walk away thinking, ‘that was easy and I got great value out of it.’”

As the novelty of legal access fades, expectations begin to mirror those of more mature consumer categories. Devices are no longer forgiven for unpredictability. Reliability becomes a baseline requirement.

Greentank’s experience in nicotine has reinforced that mindset. The company commercialized its Quantum Chip technology in European nicotine markets in 2025, allowing it to gather large-scale usage data far more quickly than cannabis alone would allow.

“The volumes on nicotine are much higher,” Gemmell said. “It enables us to understand product performance and market acceptance very quickly.”

Those insights now inform the cannabis rollout, which begins this year through a strategic, phased launch in the United States and Canada.

Personalization Without Complexity

As hardware becomes more reliable, attention is shifting toward personalization. Consumers increasingly select cannabis products based on context, time of day, or desired effect rather than brand loyalty alone. Vaporizer hardware is beginning to reflect that behavior.

“We modulate our day around how we feel at that moment,” Gemmell said. “Sometimes you want a coffee. Sometimes you want something else. Consumers are looking for the right effect right now.”

Greentank’s upcoming product pipeline includes dual-chamber all-in-ones that allow users to switch between formulations or blend them, alongside palm-styled devices with variable heat and visual feedback. The challenge lies in execution.

“You don’t want to present them with a graphic equalizer with 50,000 options,” Gemmell said. “You’ve got to keep that core simplicity.”

Designing for personalization without complexity requires restraint. Subtle temperature modulation, intuitive switching, and clear feedback are replacing dense menus and confusing interfaces. The result is hardware that feels contemporary rather than technical, borrowing cues from consumer electronics rather than smoking accessories.

Implications for Medical Cannabis

For medical patients, advances in vaporizer hardware carry added significance. Consistency is not merely a preference, but a prerequisite for confidence. Variable aerosol output or uncertain materials undermine trust in the delivery method itself.

“There’s still a little bit of a question mark with vaping in general,” Gemmell said during the interview discussion of patient use. “People don’t quite understand the mechanism of action of the hardware they’re using.”

Hardware that minimizes contaminants and delivers predictable aerosol output helps close that trust gap. In that sense, engineering rigor becomes an enabler of broader acceptance as medical and adult-use markets continue to converge.

Also read: Lawsuit Rocks Celebrity Cannabis Brand: Last Week in Weed Jan. 20-26, 2026

A Quieter Kind of Innovation

The next generation of vaporizer hardware is defined by mastery of fundamentals: fluid dynamics, thermal control, materials science, and user-centered design.

For years, cannabis hardware lagged behind the sophistication of the oils it delivered. That gap is narrowing. Devices are no longer passive containers, but active contributors to safety, flavor fidelity, and therapeutic reliability.

“We’re always thinking about the consumer,” Gemmell said. “How do we eliminate pain points, amplify what people love, and deliver something that isn’t being delivered today?”

Author

-

Aron Vaughan is a journalist, essayist, author, screenwriter, and editor based in Vero Beach, Florida. A cannabis activist and tech enthusiast, he takes great pride in bringing cutting edge content on these topics to the readers of Cannabis & Tech Today. See his features in Innovation & Tech Today, TechnologyAdvice, Armchair Rockstar, and biaskllr.