Sponsored Content

Hot, balmy weather is Florida’s claim to fame. It’s the only state in the union where pool towels mildew while hanging on the line to dry. This perpetual moisture is a challenge for Florida cultivators. While humidity can be great during the growth cycle, it’s an obstacle during the drying, trimming, and curing process — all of which are crucial to creating high-quality medical products.

There are fewer than 22 licensed cultivators providing cannabis to the entire state. These large-scale operations need to dry, trim, and cure quickly to start the next crop. Machine trimmers are often the preferred method, except they function best with dry flower — which is a challenge in 70-90% humidity.

Some innovators use carbon dioxide (CO2) as a remedy. “CO2 just flash freezes the outside of the buds so the sugar leaves get brittle and can trim really efficiently,” shared Leslie Clarke-Bruggemann, chief operating officer for Tom’s Tumbler.

The company developed a CO2 infusion adapter kit for their trimmers in early 2019. Tom’s Tumbler Trimmers are used all over the world, operating in diverse climates. Customers were asking for a solution, a gentle trimmer that would work with moist flower. The CO2 kit was an affordable option, quickly fitting onto existing Tom’s Tumbler Trimmers for an easy conversion.

Customization and affordability have been core principles for Tom’s Tumbler since they were founded in 2013. CEO and President Tom Bruggemann cultivated cannabis for more than 25 years and wanted his machines to be affordable and easy to alter. “[Bruggemann] recognizes every strain is unique and nobody knows the flower better than the grower. He gave [growers] the flexibility to tweak the angle and the meshes and the motor speed

for their buds,” shared Clarke-Bruggeman.

Now, they can also adapt machines for wet or dry trim.

The use of CO2 for the removal of moisture is a process often used in commercial food preservation. In one study titled: “Drying of foods using supercritical carbon dioxide — investigations with a carrot,” author Z.K. Brown, used X-ray microtomography and light microscopy to examine carrots that had been air-dried versus those that had been dried using CO2. Brown noted, “Drying is a common unit operation in food processing, but the rehydrated product is often of very poor quality.” He concluded, “Samples dried in [CO2]… displayed more favourable rehydrated textural properties than air-dried equivalents.”

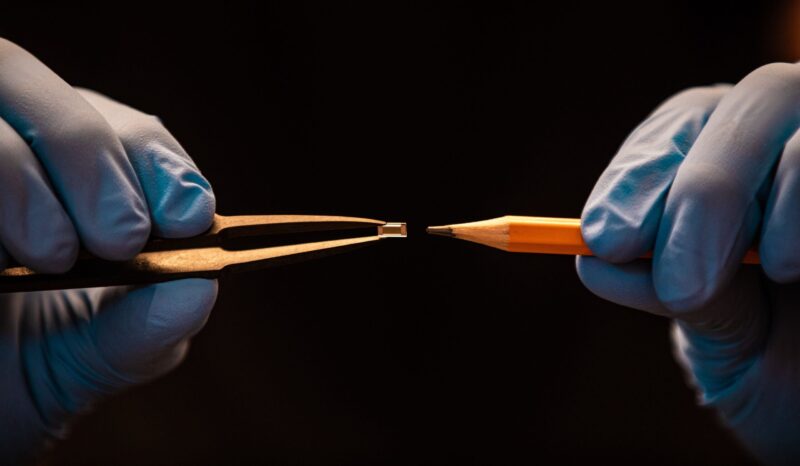

In other words, CO2 drying may actually preserve buds more effectively than air drying. Using both CO2 and bladeless trimming preserves trichomes, resulting in a more valuable final product. Tom’s Tumblers are one of the few bladeless options on the market. Clarke-Bruggeman explained, “Our machines use soft mesh net, so the trichomes and crystals are preserved in the process.”

Medical cannabis in particular should be rich in terpenes. Tikun Olam, an international medical cannabis company, is one of Tom’s Tumbler’s most notable clients. The company operates all over the globe, with one of their larger facilities located just outside of Los Angeles.

Tikun Olam uses the same equipment at their medical research headquarters in Israel as they do in California. In so doing, Tikun Olam Chief Marketing Officer Stephen Gardner noted, “we can provide our patients with the same level of consistency and continuity that we use for all our research, studies, and products that we’re developing in Israel.”

For Florida’s cannabis community, consistent products will translate to a healthier market for both growers and consumers.

All images courtesy of Tom’s Tumbler.