As cannabis continues its march toward mainstream acceptance, both in medical and recreational markets, product safety has become a paramount concern. The cultivation and processing of cannabis inherently introduces risks of microbial contamination. Pathogens like Aspergillus, Salmonella, and E. coli can compromise consumer safety and derail cultivation efforts. Rad Source Technologies, a pioneer in non-gamma irradiation, has developed cutting-edge solutions to address these issues.

Rad Since ’97

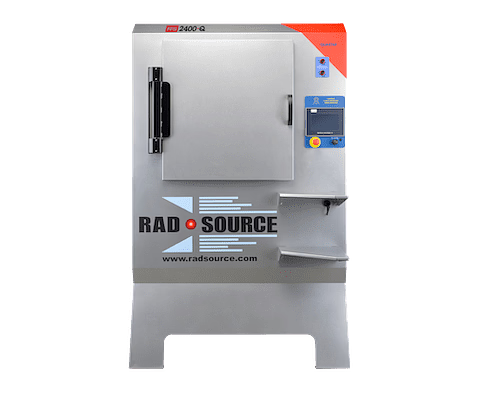

Founded in 1997, Rad Source built its reputation by advancing non-invasive decontamination technologies. Traditionally used in pharmaceutical and medical industries, their proprietary QUASTAR X-ray platform is now addressing an increasingly pressing need in the cannabis sector: reliable microbial decontamination that maintains the integrity of the plant.

“Rad Source created this market and has continued to lead and innovate,” said George Terry, Executive Vice President of Rad Source. “The cannabis industry faces significant challenges with microbial contamination, and we saw an opportunity to leverage our proven QUASTAR platform to offer cultivators a reliable, non-invasive solution that ensures product quality without compromising safety or integrity.”

Cannabis, like any agricultural product, is susceptible to contamination during cultivation, processing, and storage. High humidity levels and organic matter create an ideal environment for microbial growth, particularly molds, yeasts, and harmful bacteria. For medical cannabis patients with compromised immune systems, contaminated cannabis can pose serious health risks. Even recreational users expect products free from potentially harmful microbes.

Additionally, the legal cannabis market must comply with stringent safety standards set by regulators. Failing to meet these standards can result in rejected batches, financial losses, and reputational damage. This is where decontamination methods come into play.

Traditional approaches, such as heat treatments, ozone exposure, or chemical washes, can compromise the cannabis flower’s quality by degrading terpenes, cannabinoids, or the physical structure of the buds. Rad Source’s QUASTAR X-ray platform, however, avoids these pitfalls, offering an innovative alternative.

How Rad Source’s X-Ray Technology Works

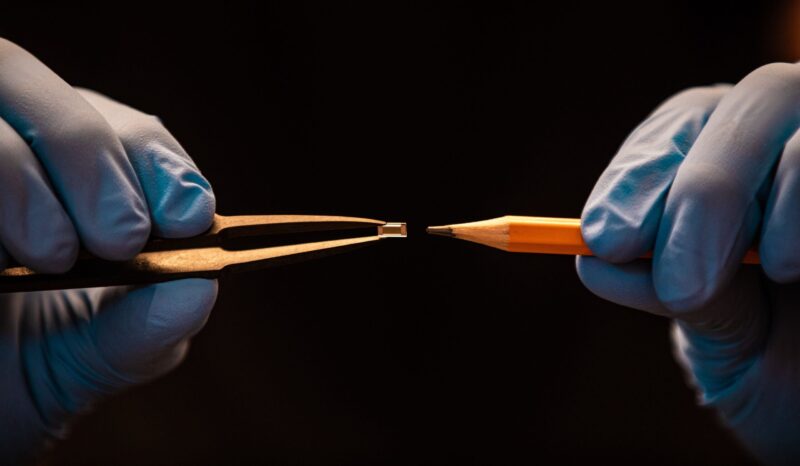

The QUASTAR X-ray platform employs “Photonic Decontamination,” a non-invasive process that targets microbial DNA without introducing heat or chemicals. The X-ray wavelengths penetrate the cannabis flower to deactivate pathogens at their genetic level, leaving them non-viable and unable to reproduce. Unlike other methods that physically alter the plant, Rad Source’s technology allows the flower to retain its cannabinoids, terpenes, and trichomes.

“We normalize the microbe at the DNA level, instead of the molecular level, leaving it non-viable,” explained Terry. “This means the cannabinoids and terpenes—the compounds responsible for the plant’s therapeutic and sensory qualities—remain intact.”

And, along with eliminating harmful pathogens, this method preserves the sensory and therapeutic qualities of cannabis so the buds remain potent and flavorful.

Why X-Ray Technology?

- Unlike heat-based methods, which can degrade the delicate compounds in cannabis, x-ray technology works without raising the temperature of the flower. This ensures the trichomes, which house cannabinoids and terpenes, remain undamaged.

- The patented Dose Carousel ensures that each batch receives consistent and uniform radiation. This eliminates the risk of untreated “hot spots,” which can occur with less precise methods.

- QUASTAR achieves a 99.9% microbial decontamination rate, meeting or exceeding safety standards across states and countries. It is particularly effective against molds and bacteria commonly found in cannabis.

- Rad Source offers solutions tailored to different operation sizes. Smaller growers can use compact systems, while large-scale producers benefit from high-capacity setups designed for efficiency.

“The system’s precise dose control and uniformity ensure that every batch is treated thoroughly,” Terry said. “Our technology consistently achieves microbial levels that meet the most stringent safety regulations.”

Building on Decades of Expertise

Rad Source’s journey into the cannabis market is a natural evolution of its legacy in other industries. From decontaminating pharmaceuticals to sterilizing medical equipment, the company has honed its X-ray technology for applications that demand precision and reliability. When they turned their attention to cannabis, they saw an opportunity to address a critical pain point with a proven, scalable solution.

“Photons are a tried-and-true method in the medical decontamination world,” Terry said. “There is a reason why Rad Source holds over 90% of the X-ray segment of the cannabis market—it works.”

Also Read: Spotlight on 2024 CannaTech Innovation Award Winner: Quest Climate

Supporting Cannabis Producers

In addition to cannabis contamination technology, Rad Source offers consultation, training, and ongoing support to ensure producers maximize the value of their investment. Systems like the RS 420∙Q+ are optimized for mid-sized cultivators but can be scaled to accommodate operations of any size.

“Our team works closely with growers to integrate solutions tailored to their production volumes and workflow needs,” Terry said. “Whether it’s a smaller operation or a large-scale producer, we ensure the same high level of efficiency and effectiveness.”

A Vision for Innovation

While they continue to refine their cannabis decontamination systems, the company is also exploring new applications for their QUASTAR technology in other industries. Their focus remains on providing sustainable, non-invasive solutions that prioritize safety and quality.

“Our vision is to continue leading the way in safe, innovative, and sustainable X-ray technology,” Terry shared. “As the global demand for safer, cleaner solutions grows, Rad Source will remain at the forefront, delivering trusted technologies that make a difference.”

The cannabis industry’s rapid growth brings both opportunities and challenges. As more consumers demand safe, high-quality products, technologies like Rad Source’s X-ray platform will play an essential role in setting industry standards. By addressing microbial contamination without compromising the plant’s integrity, Rad Source is helping cultivators meet regulatory demands while delivering products that meet the expectations of discerning consumers.

In the words of Terry: “Let’s get real. Ozone, RF, and other outdated methods don’t protect your flower. Our QUASTAR platform is built on science and decades of expertise. It works, and it makes a difference.”

Author

-

Aron Vaughan is a journalist, essayist, author, screenwriter, and editor based in Vero Beach, Florida. A cannabis activist and tech enthusiast, he takes great pride in bringing cutting edge content on these topics to the readers of Cannabis & Tech Today. See his features in Innovation & Tech Today, TechnologyAdvice, Armchair Rockstar, and biaskllr.