Cannabis innovation is often described in sweeping generalities, yet real progress occurs in precise increments, such as a cleaner extract, a smarter device, a faster machine, or a more transparent supply chain. This year’s CannaTech Innovation Awards highlight that type of progress.

The honorees represent a wide cross-section of the industry, from ingredient science and cultivation technology to hardware engineering and retail systems. Their work blends technical rigor with practical outcomes, which is what separates trend from transformation. This year’s winners are reimagining the expectations in their respective categories.

Below are the fifteen companies selected by voters and judges as the most influential innovators of 2025.

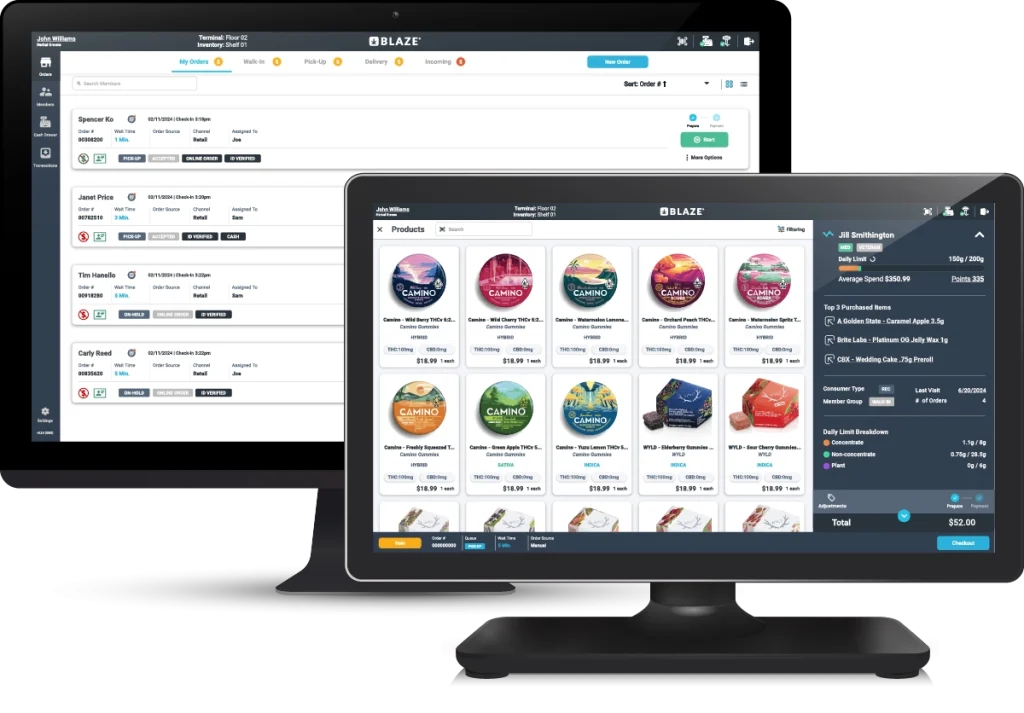

BLAZE

Retail software

BLAZE focused on a fundamental retail problem: the strain that promotion management places on multi-location dispensaries. Company Promotions was designed to remove repetitive work and give operators a streamlined system for pricing strategies. As the company explained, the tool allows retailers to “create a promotion once and apply it across all your locations in just a few clicks.” Beta users reported dramatic time savings, with BLAZE noting that early adopters saved “an incredible 90% of the labor hours they previously spent creating promotions.”

The platform also supports complex discount structures, helping businesses tailor incentives to loyalty segments without sacrificing consistency. BLAZE described it as “a smarter, more efficient approach to driving sales and customer loyalty.” The feature signals a new level of sophistication for cannabis retail software, offering both speed and precision for teams stretched thin.

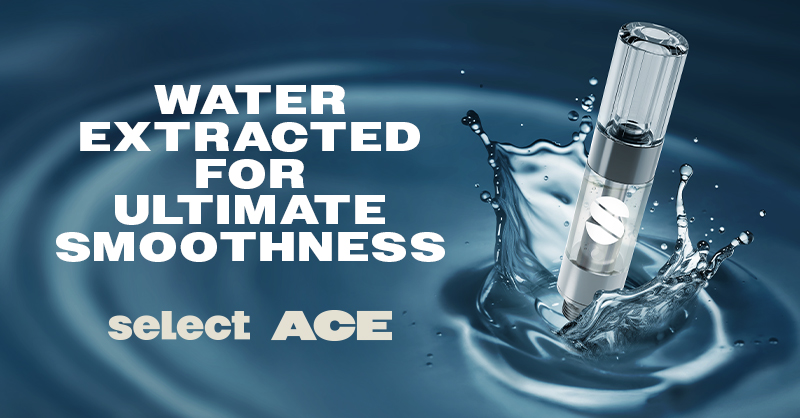

Curaleaf

Select ACE

Curaleaf introduced a water-based extraction system that reshapes expectations for vape purity. Select ACE isolates THCA without ethanol, CO₂, or hydrocarbons. “This method leaves behind the typical irritants,” the company said, referencing fats and waxes that traditionally contribute to harsh flavors and muted terpene expression. The result is a crystal-clear oil that consistently tests above 90 percent THC.

The team highlighted the combination of clarity and flavor fidelity, noting that ACE oil is infused with more than five percent strain-specific cannabis-derived terpenes. “It is crystal-clear and is infused with over five percent strain-specific cannabis-derived terpenes,” Curaleaf said. Consumer feedback has focused on reduced throat irritation and stronger terpene expression. Curaleaf framed ACE as both a technical and experiential step forward, stating that “its innovation is not just a novelty. It is the future of cannabis oil.”

STORZ & BICKEL

Certified Medical-Grade Vaporization Technology

STORZ & BICKEL continued to strengthen its reputation for medical-grade hardware built with rigorous engineering standards. The company emphasized precision heating, material integrity, and long-term reliability as the foundations of its device portfolio. The materials highlight that all components are selected for purity and safety, reflecting a manufacturing approach that has made the brand a reference point for consistent vapor quality in both medical and adult-use markets.

True Terpenes

Modifiers Line

True Terpenes approached flavor innovation through targeted enhancement rather than replacement. The Modifiers line allows product developers to introduce cooling, sweetness, or intensified pungency while keeping the original strain identity intact. “Traditional flavoring methods tend to mask or muddle the terpene profile,” the company said. Modifiers were formulated to avoid that outcome.

The team described the line as “precision-engineered,” allowing brands to dial in specific sensory effects. Customers can “launch new infused SKUs using their existing formulations,” according to early metrics. Built with individually distilled compounds and rooted in ASTM D8441 safety standards, the line gives developers a structured, reliable tool set for flavor exploration that respects strain authenticity.

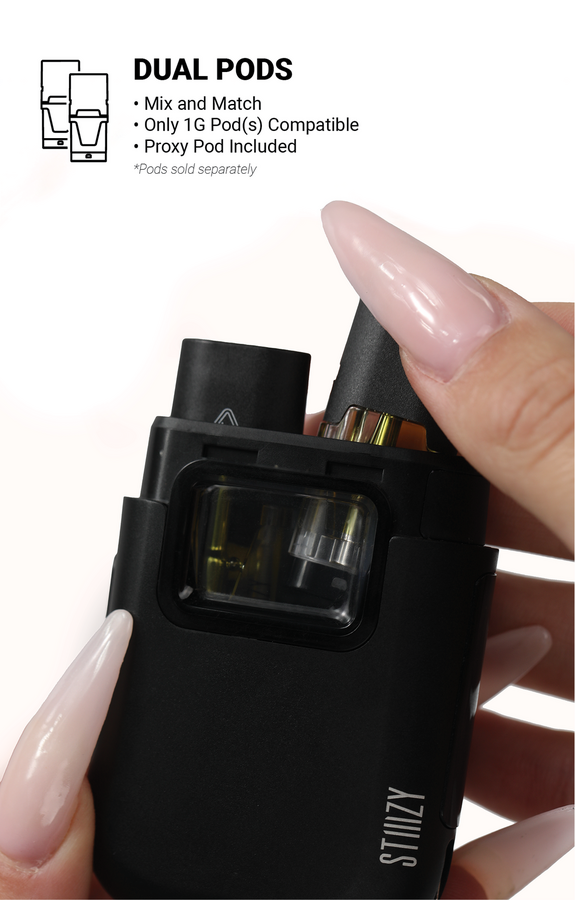

STIIIZY

STIIIZY BAR

STIIIZY advanced its hardware portfolio with a device built for personalization. The STIIIZY BAR includes adjustable voltage, variable airflow, dual activation, and a display that tracks battery life and draw duration. “The dual chambers hold two full-gram STIIIZY pods,” the team said, highlighting the device’s ability to shift quickly between strains.

The company described the device as “a precision tool for crafting your ideal cannabis experience.” Retail partners have seen increased multi-pod purchases due to the BAR’s design, paired with strong consumer interest in hardware that offers more control without added complexity. Its blend of portability, performance, and ease of use defines the current direction of premium vape engineering.

Ethos Cannabis

Remediation-Free Cultivation Model

Ethos Cannabis committed to a prevention-first cultivation philosophy that avoids the need for remediation altogether. “We do not own remediation equipment,” the company said. Instead, its system relies on linear facility layouts, strict environmental controls, and rigorous hygiene protocols that maintain microbial cleanliness.

Ethos reported a first-pass microbial test rate exceeding 97%, which it tied directly to its facility design and SOP structure. The approach preserves terpene integrity and cannabinoid profiles by eliminating exposure to radiation, ozone, or chemical sterilization. Ethos described it as “a bold, values-driven alternative” and emphasized that it protects both product quality and consumer trust.

This model has resonated particularly with medical patients and retailers who prioritize unaltered flower.

XRPure

XR16 Decontamination System

XRPure’s XR16 addressed the challenge of microbial contamination through cold X-ray technology. The company shared that the machine eliminates pathogens “up to three times faster than competing systems” while preserving terpenes, cannabinoids, and flower integrity. One customer reported being “blown away” by the system’s ease of use and efficiency.

The XR16 processes up to 100 pounds per eight-hour shift and 300 pounds per day, serving cultivators who manage high volumes and strict compliance timelines. XRPure said customers have reached “almost a 100 percent pass rate” since adopting the technology.

The system also allows operators to generate value in new ways, including toll services and leasing models that reduce capital burden. XRPure positions the XR16 as both a compliance tool and a strategic asset.

Mfused

Jefé Plus

Mfused reimagined the disposable vape with Jefé Plus, an all-in-one device equipped with real-time feedback and customizable heat settings. The company said it built Jefé Plus because users had been left guessing about oil levels, battery life, and dosing consistency. “The screen shows you your battery level and how long each hit lasts,” the team said.

Three heat settings allow consumers to match temperature to their strain or flavor preferences. Mfused explained that the goal was to combine the simplicity of a disposable with features “everyone has been asking for,” without requiring an app or external controls.

Jefé Plus has resonated with high-tolerance and tech-forward consumers who want a more intentional experience from a single-use device.

Cryo Cure

Advanced Freeze-Drying Technology

Cryo Cure offered a solution for cultivators seeking faster curing cycles and improved terpene preservation. Its system stabilizes flower structure through controlled freeze-drying that limits shrinkage and protects trichomes. Cultivators gain shorter turnaround times and more reliable product consistency, which helps them maintain inventory flow and preserve sensory quality.

Sweed

Compliance and Workflow Automation

Sweed focused on the operational bottlenecks created by compliance-heavy production pipelines. Its system organizes labeling, batch tracking, and regulatory documentation through a simplified interface that reduces repetitive data entry. Operators benefit from fewer errors and more predictable workflows. Sweed’s core value is in turning compliance into a steady, manageable process rather than an intermittent scramble.

Melt-to-Make

Pectin Gummy Base

Melt-to-Make developed a pectin gummy base designed for clean-label formulations and large-scale production. Pectin supports a stable, plant-based structure that appeals to brands moving away from gelatin. The company described its base as “the clean, scalable, and reliable foundation” for natural gummies.

Manufacturers can melt and pour the base directly, which reduces development time and allows consistent results across batches. The 550-kilogram totes provide a low-touch, high-output system for producers growing their edible lines or transitioning to allergen-friendly ingredients.

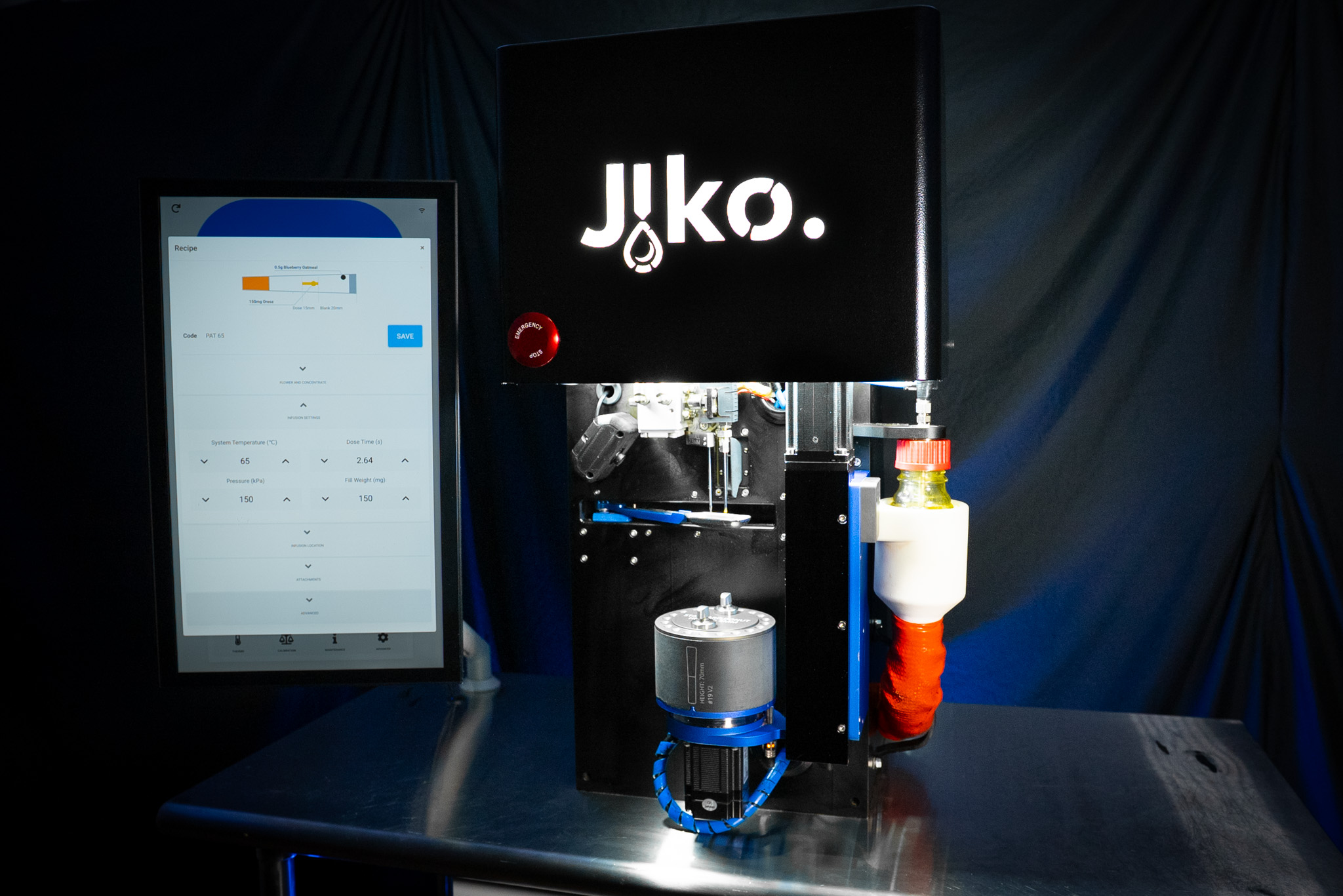

Sorting Robotics

Jiko+

Sorting Robotics expanded infused pre-roll production with Jiko+, a machine that automates donut-style hash holes with sub-millimeter accuracy. “Jiko+ allows cannabis manufacturers to create high-end hash hole pre-rolls at scale,” the company said. Before Jiko+, this category depended on labor-intensive hand craftsmanship.

The system includes six rotating infusion wheels and modular attachments that support different product formats. Customers typically reduce labor costs by 40 to 60 percent and double or quadruple throughput. Sorting Robotics said many operators see a return on investment in under a year due to SKU expansion and reduced waste.

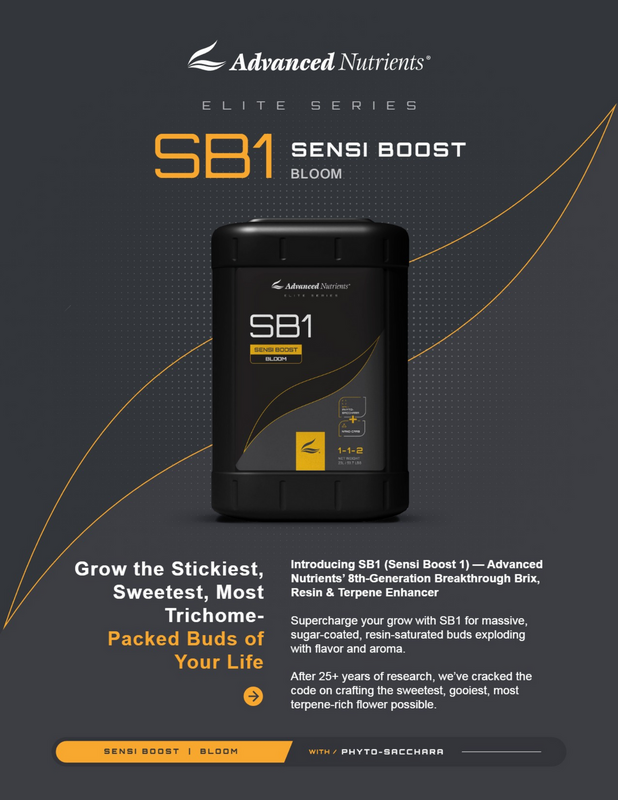

Advanced Nutrients

SB1

SB1 reframes how carbohydrate supplementation functions inside the plant by addressing a long-standing inefficiency in conventional sugar additives. Rather than feeding microbes in the root zone, its NanoCarb delivery system enables sugars to be absorbed directly at the molecular level, supporting measurable increases in brix levels, terpene expression, and resin production. Paired with a fermented sugarcane–derived biostimulant, the formulation is designed to support trichome density and flavor development during the stages when plants are most metabolically active.

In practice, SB1’s value shows up in consistency as much as output. Growers report more uniform maturation, stronger aroma profiles, and improved visual appeal across harvests, factors that increasingly influence wholesale pricing in saturated markets. By reducing wasted inputs and translating plant physiology into tangible quality gains, the product positions carbohydrate supplementation as a precision tool rather than a blunt additive, aligning crop performance with both agronomic and economic realities.

Azuca

Whole-Plant ACTiVATOR

Azuca created a water-based infusion technology that captures the full cannabinoid and terpene profile of flower without using solvents. “The process maintains strain-specific flavors and aromas,” the team said. The method also cuts production costs by as much as 70 percent when compared with solventless extracts.

The ACTiVATOR delivers effects within five to fifteen minutes and preserves natural flavor without masking agents. Azuca described the result as “a genuine whole-plant experience,” bridging sustainability, efficiency, and clean-label formulation trends. It is already powering more than 150 SKUs nationwide.

CCELL

Ceramic Heating Technology

CCELL refined the ceramic heating core that has become synonymous with clean, consistent vaporization. The company’s focus on even heat distribution and inert materials has helped producers preserve terpene integrity and avoid burnt flavors or clogging. Its technology has become a backbone for many premium vape lines seeking reliability at scale.